Product Lifecycle Management (PLM) is rapidly transforming the food and beverage industry. In today’s competitive market, companies are constantly seeking ways to optimize their processes, improve product quality, and meet evolving consumer demands. PLM offers a comprehensive solution that addresses these challenges and more, enabling food and beverage businesses to thrive in a complex and ever-changing landscape.

What is PLM and Why is it Important for Food and Beverage?

Plm For Food And Beverage encompasses the management of all information related to a product, from its initial conception and development to its eventual retirement from the market. This includes managing formulations, ingredients, packaging, labeling, regulatory compliance, and more. It streamlines these processes, reduces errors, and accelerates time to market. Why is this crucial? Because in an industry where consumer preferences shift rapidly and regulations are constantly evolving, agility and efficiency are key to success.

Benefits of Implementing PLM in the Food and Beverage Industry

Implementing PLM systems brings a plethora of benefits to food and beverage companies. These include:

- Improved Product Quality and Safety: PLM enables businesses to track ingredients and formulations meticulously, ensuring consistency and adherence to quality and safety standards.

- Enhanced Collaboration: PLM facilitates seamless communication and collaboration between different departments, suppliers, and partners, fostering innovation and reducing development time.

- Streamlined Regulatory Compliance: Navigating complex food safety regulations can be a daunting task. PLM systems help companies manage compliance requirements efficiently, minimizing the risk of costly penalties and recalls.

- Reduced Time to Market: By optimizing processes and improving collaboration, PLM helps bring products to market faster, capturing valuable market share.

- Increased Profitability: By reducing waste, streamlining operations, and improving efficiency, PLM contributes to increased profitability and a healthier bottom line.

How Does PLM Address Key Challenges in the Food and Beverage Industry?

The food and beverage sector faces unique challenges that PLM is particularly well-suited to address. Consider the complexities of managing diverse ingredient lists, ensuring accurate labeling information across multiple markets, and responding swiftly to changing consumer demands. PLM provides the tools and framework to navigate these complexities effectively.

Navigating Complex Regulatory Landscapes

Food safety regulations are constantly evolving, and keeping up with the latest requirements can be a significant burden. PLM systems provide a centralized platform for managing regulatory information, ensuring that products comply with all applicable rules and regulations.

Meeting Evolving Consumer Demands

Consumers are increasingly health-conscious and demanding transparency about the ingredients and sourcing of their food. PLM enables companies to respond to these demands by providing accurate and detailed product information, building trust and loyalty.

Food Safety Regulation Compliance with PLM

Food Safety Regulation Compliance with PLM

Choosing the Right PLM Solution for Your Food and Beverage Business

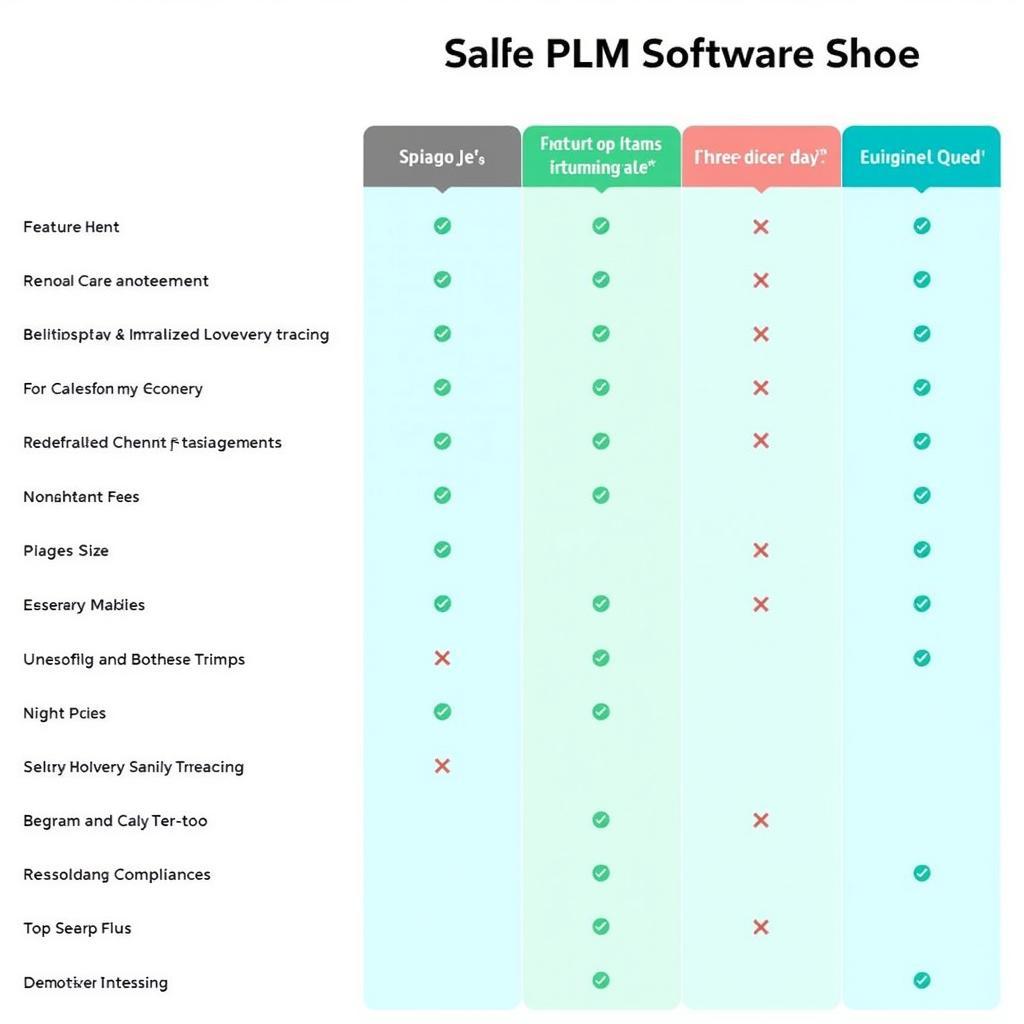

Selecting the appropriate PLM solution is crucial for maximizing its benefits. Consider factors like the size of your business, your specific needs and challenges, and your budget.

Key Considerations for Selecting a PLM System

- Scalability: Choose a PLM system that can scale with your business as it grows.

- Integration: Ensure that the PLM system can integrate with your existing ERP and other business systems.

- User-Friendliness: A user-friendly interface is essential for ensuring adoption and maximizing the value of the PLM system.

“Choosing the right PLM system is a critical investment,” says Sarah Miller, a leading food industry consultant. “It’s essential to carefully evaluate your needs and select a solution that aligns with your business goals.”

PLM Software Selection for the Food Industry

PLM Software Selection for the Food Industry

Conclusion: Unlocking the Power of PLM for Food and Beverage

PLM for food and beverage is no longer a luxury but a necessity in today’s competitive market. By implementing a robust PLM solution, businesses can optimize their processes, enhance product quality and safety, and meet evolving consumer demands. Embrace the power of PLM and unlock the recipe for success in the food and beverage industry.

FAQ

- What is the cost of implementing a PLM system? The cost varies depending on the size of your business and the complexity of the system.

- How long does it take to implement a PLM system? Implementation timelines typically range from several months to a year.

- What are the key features of a good PLM system for food and beverage? Key features include ingredient tracking, recipe management, and regulatory compliance tools.

- How does PLM improve product safety? PLM enables companies to track ingredients and formulations meticulously, ensuring adherence to quality and safety standards.

- What are the benefits of using PLM for regulatory compliance? PLM helps manage compliance requirements efficiently, minimizing the risk of penalties and recalls.

- How can PLM help my business grow? PLM optimizes processes, reduces time to market, and improves efficiency, contributing to business growth.

- What are the best practices for implementing a PLM system? Best practices include thorough planning, stakeholder engagement, and ongoing training.

Need assistance with PLM for your Food and Beverage business? Contact us! Phone: 02437655121, Email: minacones@gmail.com or visit our office at 3PGH+8R9, ĐT70A, thôn Trung, Bắc Từ Liêm, Hà Nội, Việt Nam. We offer 24/7 customer support. We also have a blog post on “Optimizing your Supply Chain with PLM” and “The Future of Food Safety with PLM Technology” that you may find helpful.