Hydrogen Peroxide Food Grade 35 is a powerful oxidizing agent with various applications, particularly in food processing and sanitation. This guide will explore its uses, safety precautions, and the importance of choosing a reputable supplier like Mina Cones Food. 35 percent food grade hydrogen peroxide requires careful handling and dilution for specific purposes.

Understanding Hydrogen Peroxide Food Grade 35

Food grade hydrogen peroxide, specifically at a 35% concentration, is significantly stronger than the typical 3% solution found in drugstores. Its higher concentration makes it extremely effective for specific applications within the food industry but also demands careful handling. Understanding the difference between food grade and other grades of hydrogen peroxide is crucial. Non-food grade varieties may contain stabilizers and other additives unsuitable for consumption.

What sets food-grade hydrogen peroxide apart is its purity. It meets stringent standards to ensure it’s free from contaminants that could compromise food safety. This makes it suitable for various applications, from sanitizing equipment to specific food processing techniques.

Applications of Hydrogen Peroxide 35% in Food Processing

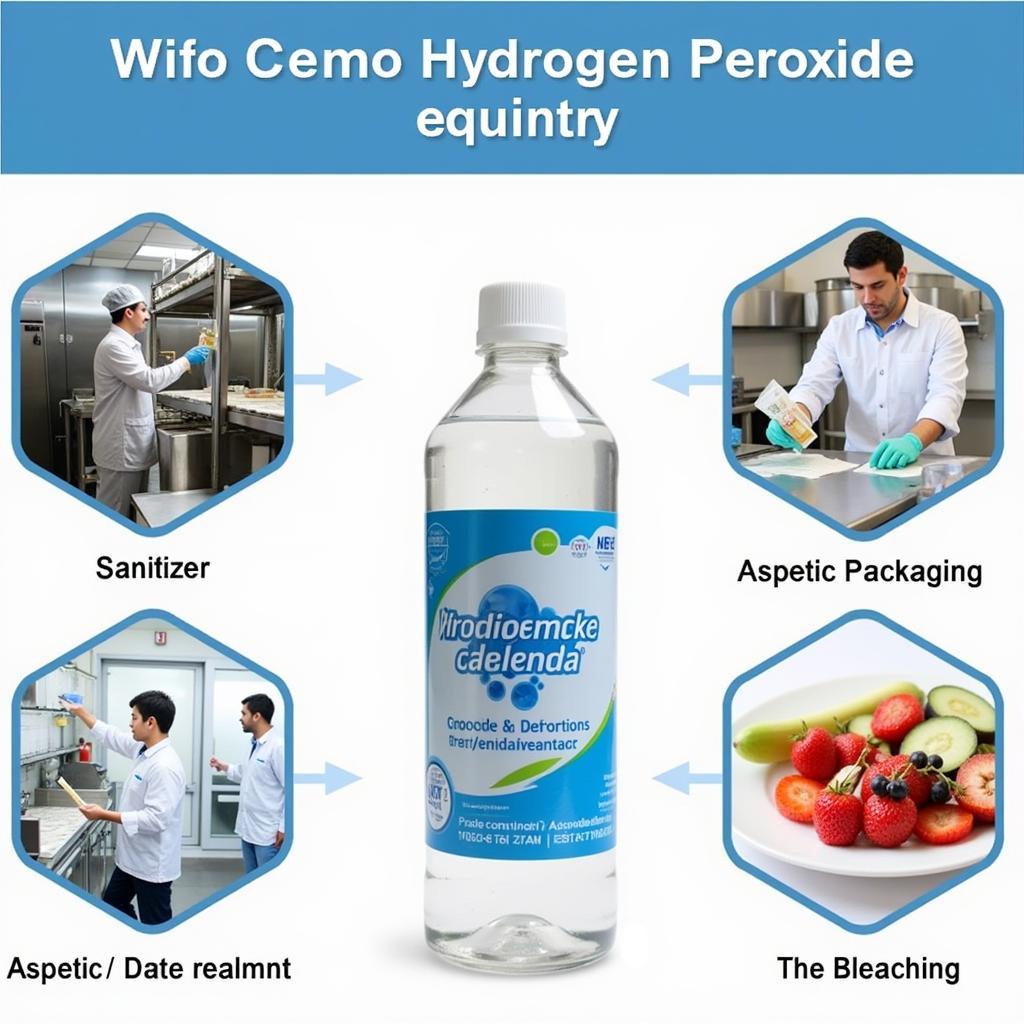

Hydrogen peroxide food grade 35 plays a vital role in maintaining hygiene and quality in the food industry. It’s commonly used for sanitizing surfaces, equipment, and packaging materials, effectively eliminating bacteria, viruses, and fungi. Additionally, it’s employed in aseptic packaging systems to sterilize packaging before filling it with food products, extending shelf life and preventing spoilage.

Beyond sanitation, hydrogen peroxide 35% can be used in specific food processing methods, such as bleaching certain food products like cheese or whey. It also plays a role in oxidizing undesirable compounds, contributing to the overall quality and safety of the final product.

What are some specific examples? Imagine a cheesemaker ensuring the hygiene of their equipment with a diluted solution of hydrogen peroxide 35 food grade, or a beverage producer utilizing it in their aseptic packaging process. These examples highlight its versatility and importance in modern food production.

Hydrogen Peroxide in Food Processing and Sanitation

Hydrogen Peroxide in Food Processing and Sanitation

Safety Precautions When Handling Hydrogen Peroxide Food Grade 35

Handling hydrogen peroxide food grade 35 requires strict adherence to safety guidelines. Its high concentration poses potential risks if not handled properly. Always wear appropriate personal protective equipment (PPE), including gloves, eye protection, and a respirator, to prevent contact with skin and eyes. Store it in a cool, dry, and well-ventilated area, away from incompatible substances and direct sunlight. Always dilute it to the appropriate concentration before use, following recommended guidelines and safety data sheets.

Why is proper dilution critical? Using undiluted 35% hydrogen peroxide can be hazardous and damage equipment or food products. Accurate dilution ensures efficacy and safety. Remember, improper handling can lead to serious health risks.

Choosing a Reputable Supplier: The Importance of Quality and Trust

Selecting a trustworthy supplier is paramount when sourcing 35 percent hydrogen peroxide food grade. A reputable supplier, like Mina Cones Food, guarantees the quality and purity of the product, adhering to strict industry standards. They provide detailed product information, safety data sheets, and expert guidance on proper handling and usage. Partnering with a reliable supplier ensures you receive a product that meets food safety regulations, protecting consumers and your brand reputation.

Conclusion: Harnessing the Power of Hydrogen Peroxide Food Grade 35 Safely

Hydrogen peroxide food grade 35 is an invaluable tool in the food industry. Its powerful oxidizing properties contribute to sanitation, food processing, and ensuring product quality. However, its potency necessitates careful handling and adherence to safety protocols. By choosing a reputable supplier like Mina Cones Food and following recommended guidelines, you can safely harness the benefits of hydrogen peroxide food grade 35, contributing to a safer and more efficient food production process.

FAQ

-

What is the difference between food grade and regular hydrogen peroxide? Food grade hydrogen peroxide has a higher purity level and is free from additives found in regular varieties.

-

How do I dilute 35% hydrogen peroxide for sanitizing surfaces? Refer to the safety data sheet and supplier guidelines for specific dilution instructions.

-

What PPE should I wear when handling 35% hydrogen peroxide? Gloves, eye protection, and a respirator are essential.

-

Where should I store hydrogen peroxide 35%? Store it in a cool, dry, well-ventilated area, away from incompatible substances and direct sunlight.

-

Why is choosing a reputable supplier important? A reputable supplier guarantees product quality and purity, adhering to industry standards and providing necessary safety information.

Common Situations and Questions:

Scenario: You need to sanitize your food processing equipment.

Question: What dilution of hydrogen peroxide 35% is appropriate for this purpose?

Scenario: You spilled some 35% hydrogen peroxide.

Question: What are the immediate steps to take?

Further Reading and Resources:

For more information on food safety and sanitation, explore our other articles on 35 percent food grade hydrogen peroxide.

Need Help? Contact Us!

For further assistance and inquiries, contact us at Phone: 02437655121, Email: minacones@gmail.com or visit us at 3PGH+8R9, ĐT70A, thôn Trung, Bắc Từ Liêm, Hà Nội, Việt Nam. Our customer service team is available 24/7.