Food safety is paramount in any food processing or handling environment. A crucial component in maintaining this safety is the use of a Food Safe Pump. Choosing the correct pump ensures product integrity and protects consumers from potential harm. Let’s delve into the world of food safe pumps and explore how they contribute to a safe and efficient food processing operation.

What is a Food Safe Pump?

Food safe pumps are specifically designed to handle various food products while adhering to strict hygiene standards. These pumps prevent contamination, preserve product quality, and maintain the overall safety of the food supply chain. They are constructed from materials that comply with FDA regulations and are designed to be easily cleaned and sanitized. Selecting a suitable food safe pump can significantly impact the efficiency and hygiene of your food processing operations. You might be interested in our food grade pump.

What materials are food safe pumps made of? Food safe pumps are typically constructed from stainless steel, which is resistant to corrosion and easy to clean. Other materials, such as specific plastics and elastomers, may also be used, depending on the application.

Why are food safe pumps important? Using a food safe pump is essential for preventing contamination and preserving the quality of food products. They contribute significantly to maintaining hygiene standards and ensuring consumer safety.

Types of Food Safe Pumps

Various types of food safe pumps cater to different food processing needs. These include centrifugal pumps, positive displacement pumps (like rotary lobe pumps and food grade gear pump), and diaphragm pumps. Each pump type offers unique advantages and is suited for specific applications, from handling viscous liquids like sauces to transferring delicate fruits and vegetables.

Choosing the Right Food Safe Pump for Your Needs

Selecting the appropriate food safe pump requires careful consideration of several factors:

- Product Viscosity: Thick liquids require pumps capable of handling high viscosity without damaging the product.

- Temperature Sensitivity: Some food products are sensitive to temperature changes. A pump that minimizes heat generation is crucial for these applications.

- Cleanability: Ease of cleaning and sanitization is paramount to prevent bacterial growth and cross-contamination.

- Flow Rate: The required flow rate determines the pump’s capacity and ensures efficient processing.

Various Food Safe Pump Types

Various Food Safe Pump Types

Choosing the correct pump ensures the efficient and hygienic processing of your food products. Are you looking for a reliable solution for spraying food-grade liquids? Check out our food grade pump sprayer.

Maintaining Your Food Safe Pump

Regular maintenance is vital to ensure the longevity and performance of your food safe pump. Proper cleaning and sanitization prevent bacterial buildup and maintain hygiene standards. Routine inspections can identify potential issues early on, minimizing downtime and costly repairs.

Cleaning and Sanitization Best Practices

- Disassembly: Properly disassemble the pump according to the manufacturer’s instructions.

- Cleaning: Use appropriate cleaning agents that are compatible with the pump materials and remove all food residue.

- Sanitization: Sanitize all parts using approved sanitizers to eliminate bacteria and other microorganisms.

- Reassembly: Carefully reassemble the pump, ensuring all parts are correctly fitted and secured.

Maintaining a Food Safe Pump

Maintaining a Food Safe Pump

“Regular maintenance is not just about keeping the equipment running; it’s about upholding the highest standards of food safety,” says renowned food safety consultant, Dr. Amelia Hernandez.

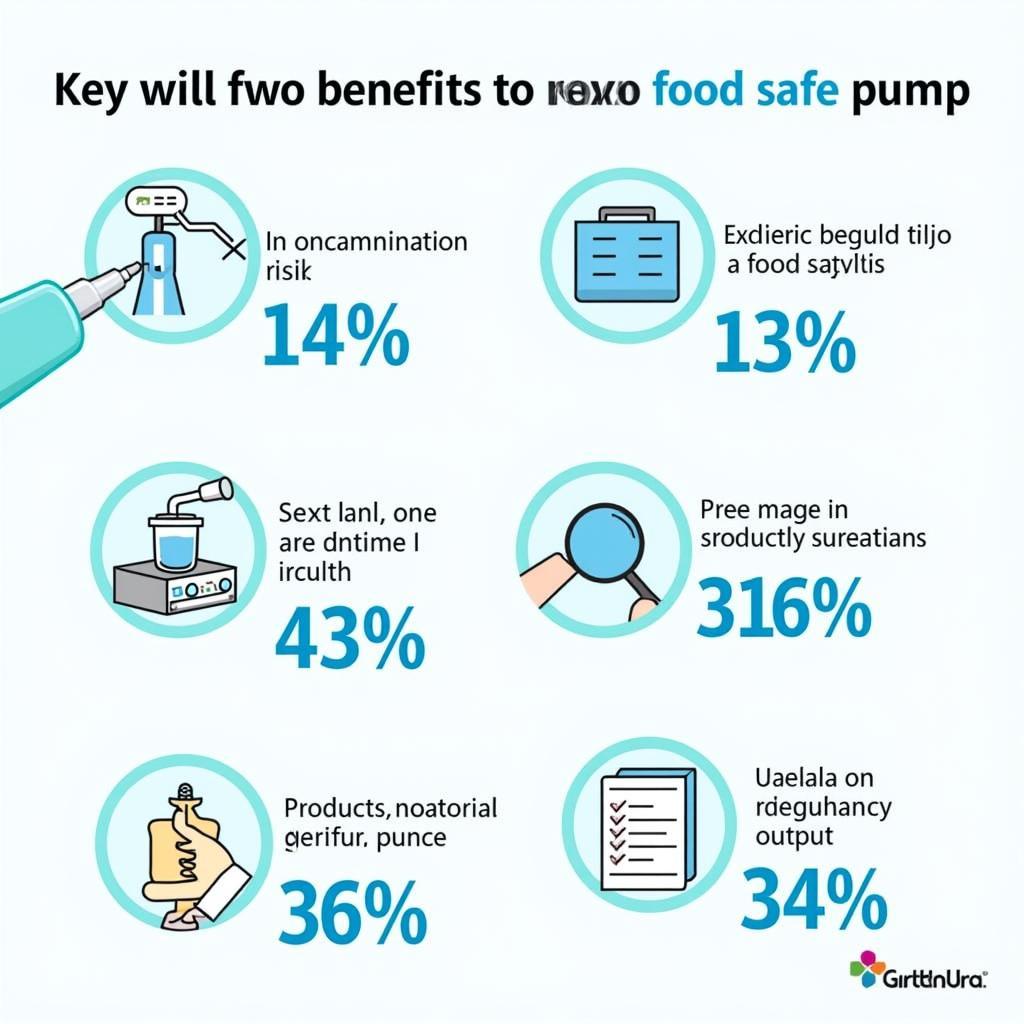

Benefits of Using a Food Safe Pump

Investing in a food safe pump offers numerous benefits:

- Enhanced Food Safety: Minimizes the risk of contamination and ensures product integrity.

- Improved Product Quality: Gentle handling preserves the texture and flavor of delicate food items.

- Increased Efficiency: Optimizes processing speed and reduces downtime.

- Compliance with Regulations: Meets stringent food safety regulations and standards.

“A food safe pump is an investment in the long-term success of your food processing business,” adds Dr. Hernandez.

Are you in need of reliable food trays? Check out our save a day food tray and plastic trays with lids for food.

Benefits of Using a Food Safe Pump

Benefits of Using a Food Safe Pump

Conclusion

A food safe pump is an indispensable tool for maintaining food safety and efficiency in any food processing environment. Choosing the correct pump and implementing proper maintenance procedures are crucial steps in protecting consumers and ensuring the quality of your food products. Investing in a food safe pump is an investment in the future of your business and the well-being of your customers.

FAQs

- What materials are typically used in food safe pumps?

- What are the different types of food safe pumps available?

- How do I choose the right food safe pump for my application?

- What are the key maintenance practices for food safe pumps?

- What are the benefits of using a food safe pump?

- Where can I find reliable suppliers of food safe pumps?

- How often should I replace the seals in my food safe pump?

Common Scenarios and Questions

Scenario: Dealing with highly viscous liquids like honey.

Question: What type of food safe pump is best suited for handling viscous materials?

Scenario: Transferring delicate fruits like berries without damage.

Question: Which pump minimizes product damage during transfer?

Scenario: Cleaning and sanitizing the pump after use.

Question: What are the recommended cleaning agents and sanitizers?

Further Exploration

For more information on food-grade equipment and related topics, please explore other articles on our website. You can also contact us directly for personalized assistance.

When you need assistance, please contact us: Phone: 02437655121, Email: minacones@gmail.com Or visit us at: 3PGH+8R9, ĐT70A, thôn Trung, Bắc Từ Liêm, Hà Nội, Việt Nam. We have a 24/7 customer support team.