Food Packaging Seals are crucial for maintaining product freshness, quality, and safety. They protect food from contamination, preserve its flavor, and extend shelf life. From simple plastic wrap to complex tamper-evident seals, understanding the different types and functionalities of food packaging seals is essential for any food business or conscious consumer.

Why Are Food Packaging Seals So Important?

Food packaging seals play a vital role in protecting your food products. They act as a barrier against external elements like moisture, oxygen, and contaminants, ensuring your food remains fresh and safe for consumption. Without effective seals, food can spoil quickly, leading to waste and potential health hazards. Moreover, strong seals contribute to brand reputation, reassuring customers of the product’s quality and integrity.

Proper seals maintain the nutritional value of food by preventing vitamin and mineral loss. They also help retain flavor and aroma, ensuring a satisfying culinary experience. food making machine can create high-quality products, but proper sealing is essential to preserve their integrity.

Exploring Different Types of Food Packaging Seals

From the everyday cling film to sophisticated tamper-proof closures, there’s a wide array of food packaging seals available. Each offers distinct benefits depending on the product and its specific needs.

- Heat Seals: These seals are created using heat and pressure to fuse two layers of packaging material together. Commonly used for plastic bags and pouches, heat seals offer a simple yet effective way to protect food from contaminants.

- Induction Seals: Utilizing electromagnetic induction, these seals create a hermetic barrier directly onto the container opening, ensuring product freshness and preventing leakage. They are particularly popular for liquids and powders.

- Vacuum Seals: By removing air from the packaging before sealing, vacuum seals significantly extend shelf life by inhibiting the growth of microorganisms. This method is ideal for preserving meat, cheese, and other perishable items.

- Tamper-Evident Seals: These seals provide an extra layer of security by visually indicating if a package has been opened or tampered with. They offer peace of mind to consumers and deter product theft. You might consider food tray sealer to achieve high-quality tamper-evident seals.

Choosing the Right Food Packaging Seal for Your Needs

Selecting the right food packaging seal is crucial for maximizing product shelf life and maintaining its quality. Factors like the type of food, its moisture content, storage conditions, and shelf life requirements all play a role in choosing the optimal seal.

For instance, dry goods like crackers or cereals may benefit from a simple heat seal, while liquids require a more robust seal like an induction or vacuum seal. Perishable items like fresh produce or meat demand airtight seals to prevent spoilage. If you are looking for packaging solutions, exploring wholesale food packaging boxes can provide various options.

What are the common mistakes when using food packaging seals?

Common mistakes include using incorrect temperatures for heat sealing, improper alignment of sealing materials, and insufficient pressure during the sealing process. These errors can lead to weak seals, compromising product integrity. Knowing how to avoid these pitfalls is crucial for achieving optimal results and protecting your products.

“A strong seal is the first line of defense in maintaining food safety and preventing waste,” says renowned food scientist, Dr. Amelia Hernandez. “Investing in high-quality food packaging seals is an investment in the long-term success of any food business.”

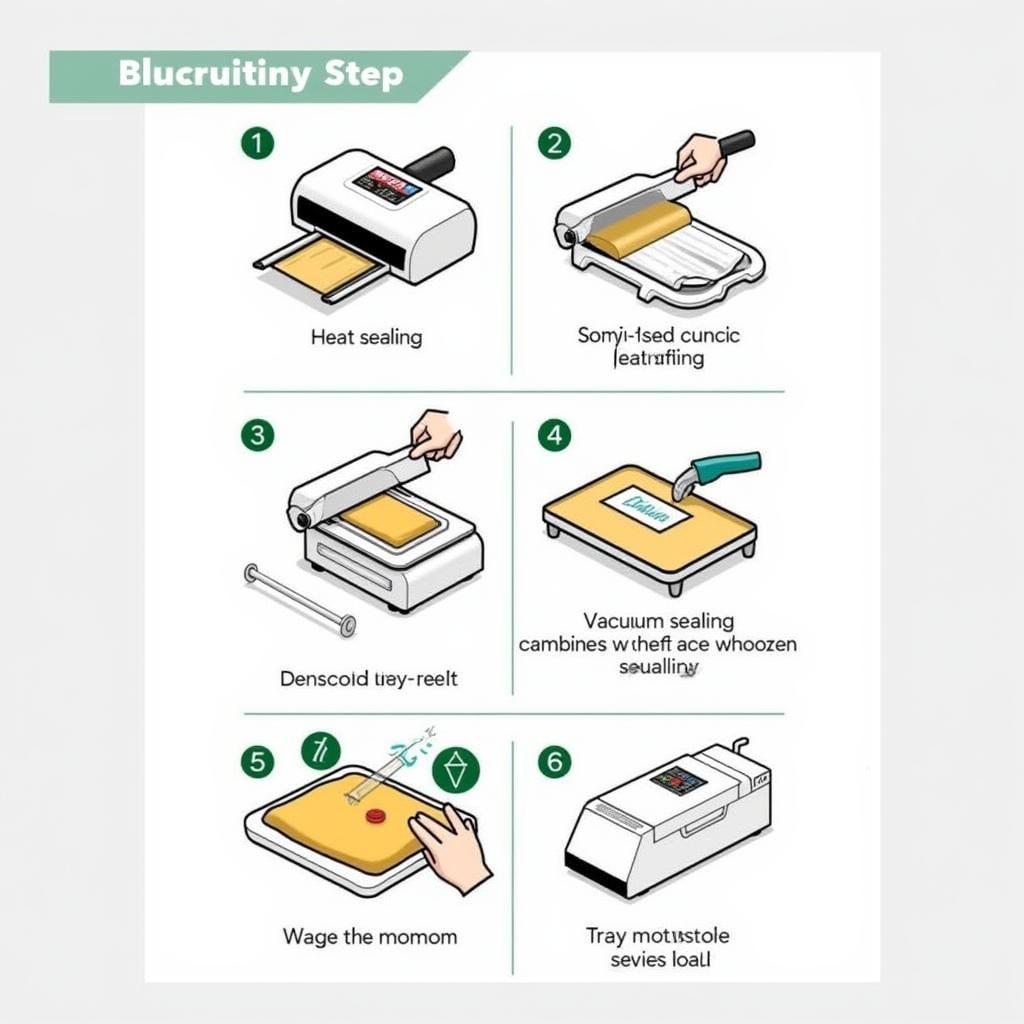

Food Packaging Sealing Process

Food Packaging Sealing Process

Food Packaging Seal Integrity Testing

Ensuring the effectiveness of your food packaging seals is crucial. This is where food packaging seal integrity testing comes in. Testing helps identify potential weaknesses or leaks in your seals, allowing you to make necessary adjustments to your packaging process. This proactive approach ensures the safety and quality of your products and protects your brand reputation.

A reliable food packing box should always be paired with a proper sealing method.

Conclusion

Food packaging seals are a fundamental aspect of the food industry, impacting everything from product safety to brand reputation. Choosing the right seal and ensuring its integrity is vital for maintaining product freshness, minimizing waste, and building consumer trust. By understanding the nuances of food packaging seals, businesses can make informed decisions that benefit both their bottom line and the satisfaction of their customers.

FAQ

- What is the purpose of food packaging seals? (To protect food from contamination and preserve its quality)

- What are the different types of food packaging seals? (Heat seals, induction seals, vacuum seals, tamper-evident seals)

- How do I choose the right food packaging seal? (Consider the type of food, its moisture content, and shelf life requirements)

- Why is seal integrity testing important? (To identify weaknesses and ensure product safety)

- Where can I find high-quality food packaging seals? (Contact Mina Cones Food for a variety of options)

- What are some common materials used in food packaging seals? (Plastic, foil, paper)

- How do tamper-evident seals enhance food safety? (By indicating if a package has been opened or tampered with)

Common Food Packaging Seal Scenarios:

- Scenario 1: Leaky juice containers – This can be due to a faulty seal or the wrong type of seal for the product.

- Scenario 2: Stale chips – A weak seal can allow air and moisture in, compromising the crispness.

- Scenario 3: Mold growth in sealed packages – Indicates a compromised seal that allowed microbial growth.

Suggested Further Reading:

- Explore our article on food tray sealer for a deep dive into tray sealing technology.

- Learn more about efficient food production with our food making machine guide.

Need further assistance? Contact us at Phone: 02437655121, Email: minacones@gmail.com or visit us at 3PGH+8R9, ĐT70A, thôn Trung, Bắc Từ Liêm, Hà Nội, Việt Nam. We offer 24/7 customer support.