Food Manufacturing Flooring is a critical component of any food processing facility. It plays a vital role in maintaining hygiene, ensuring safety, and promoting efficiency. Choosing the right flooring can significantly impact your business’s success. This guide will delve into the essential aspects of food manufacturing flooring, covering everything from material selection to installation and maintenance.  Hygienic Food Manufacturing Flooring

Hygienic Food Manufacturing Flooring

Key Considerations for Choosing Food Manufacturing Flooring

Selecting appropriate flooring for a food manufacturing environment involves considering various factors. These include resistance to chemicals, temperature fluctuations, and impact. The floor must also be easy to clean and sanitize to prevent bacterial growth and contamination. Slip resistance is crucial for worker safety, especially in wet areas. What’s more, the flooring should comply with all relevant health and safety regulations. Durability is also a key factor, as the floor needs to withstand heavy traffic and equipment. Finally, the life-cycle cost, including installation, maintenance, and repair, should be taken into account.

Understanding Different Flooring Materials

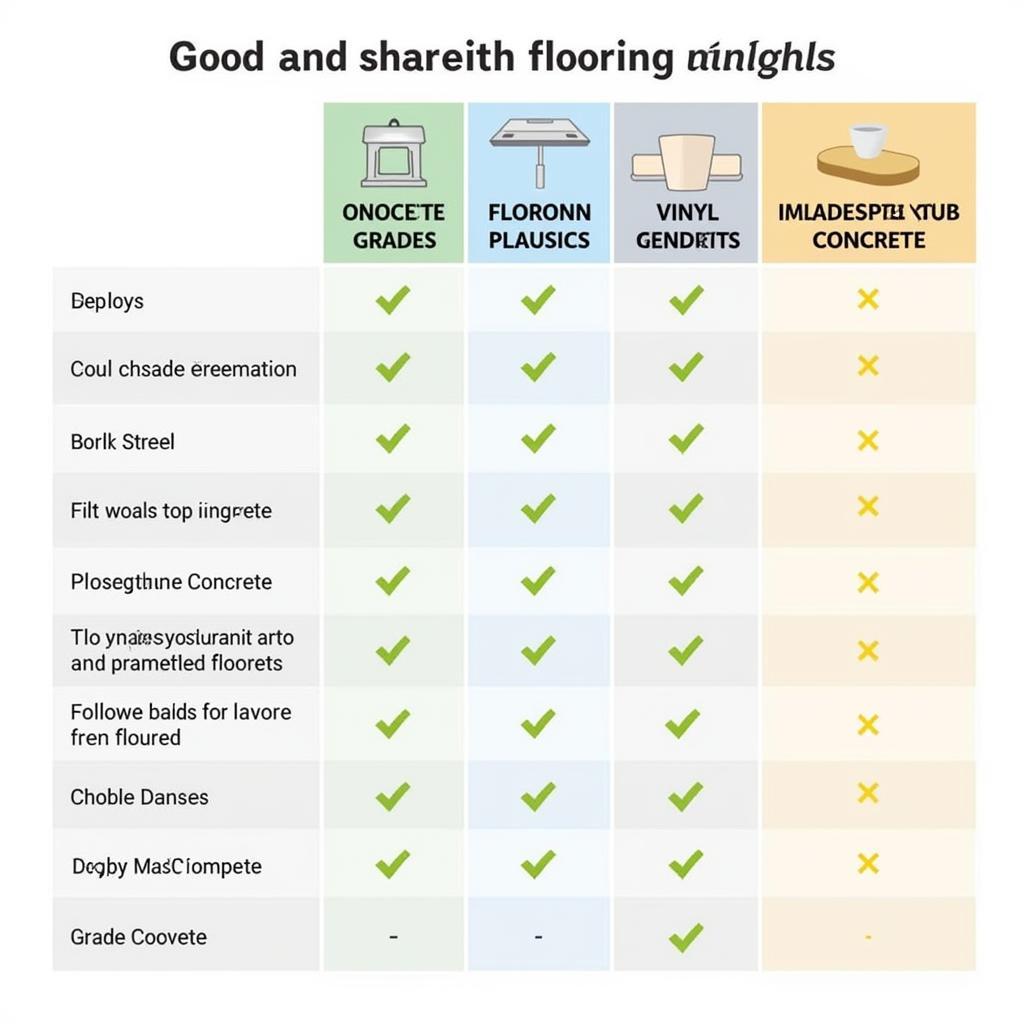

Several flooring options are available for food manufacturing facilities, each with its own advantages and disadvantages. Epoxy flooring is a popular choice due to its seamless, non-porous surface, which is easy to clean and resistant to chemicals and bacteria. Polyurethane concrete offers excellent impact and abrasion resistance, making it suitable for high-traffic areas.  Different Food-Grade Flooring Options Vinyl flooring is a cost-effective option that provides good slip resistance and is available in various colors and patterns. Choosing the right material depends on the specific needs of the facility, considering the type of food being processed, the level of traffic, and the cleaning regime. Do you prioritize chemical resistance or impact resistance? Your specific needs will dictate the best choice.

Different Food-Grade Flooring Options Vinyl flooring is a cost-effective option that provides good slip resistance and is available in various colors and patterns. Choosing the right material depends on the specific needs of the facility, considering the type of food being processed, the level of traffic, and the cleaning regime. Do you prioritize chemical resistance or impact resistance? Your specific needs will dictate the best choice.

Installation and Maintenance Best Practices

Proper installation is crucial for the longevity and performance of food manufacturing flooring. The subfloor must be properly prepared to ensure a smooth and even surface. Seamless installation is essential to prevent cracks and crevices where bacteria can harbor. Adequate curing time is necessary for the flooring to reach its full strength and resistance properties. What about maintenance? Regular cleaning and sanitation are vital to maintain hygiene and prevent contamination. whole foods cork recycling 2023 A well-maintained floor also contributes to worker safety by reducing the risk of slips and falls. Implementing a preventative maintenance program can extend the lifespan of the flooring and minimize downtime.

Why is Proper Drainage Important?

Effective drainage is essential in food processing areas. Standing water can create a breeding ground for bacteria and increase the risk of slips and falls. Proper sloping of the floor towards drains ensures efficient removal of liquids. Regular inspection and cleaning of drains are crucial to prevent blockages and maintain hygiene.

Meeting Regulatory Requirements

Food manufacturing facilities must comply with strict hygiene and safety regulations. Flooring plays a critical role in meeting these requirements. The chosen flooring material must be approved for use in food processing environments. food for less contract Proper installation and maintenance documentation is essential for compliance audits. Staying updated on the latest regulations and best practices is key to ensuring a safe and hygienic environment.

Conclusion

Investing in high-quality food manufacturing flooring is crucial for the success of any food processing operation. By carefully considering factors such as material selection, installation, maintenance, and regulatory compliance, you can create a safe, hygienic, and efficient working environment. Choosing the right food manufacturing flooring not only protects your products and employees but also contributes to the long-term profitability of your business. is pvc food grade

Expert Insights:

- John Miller, Food Safety Consultant: “Food safety starts from the ground up. Investing in appropriate flooring is a non-negotiable aspect of a robust food safety plan.”

- Sarah Lee, Facility Manager: “Properly installed and maintained flooring can significantly reduce the risk of accidents and contamination, leading to increased productivity and profitability.”

- David Chen, Flooring Specialist: “Choosing the right flooring material depends on the specific needs of the facility. A thorough assessment of the environment and operations is crucial for making the best choice.”

FAQ:

- What is the best flooring for a wet processing area?

- How often should food manufacturing flooring be cleaned?

- What are the regulatory requirements for food manufacturing flooring?

- How can I extend the lifespan of my food manufacturing flooring?

- What are the different types of drainage systems for food processing facilities?

- What is the average cost of installing food manufacturing flooring?

- How do I choose a reputable flooring installer?

Contact Us: For further assistance, please contact us at Phone Number: 02437655121, Email: minacones@gmail.com or visit our address: 3PGH+8R9, ĐT70A, thôn Trung, Bắc Từ Liêm, Hà Nội, Việt Nam. We have a 24/7 customer service team.