Food Industry Valves are essential components in various food processing applications. From controlling the flow of ingredients to ensuring product safety and maintaining hygiene standards, these specialized valves play a critical role. Understanding their diverse types, functionalities, and maintenance requirements is crucial for any food processing operation. After reading this, you’ll be able to select the perfect valves for your needs. Check out our food grade ibc tote for your bulk liquid storage needs!

Different Types of Food Industry Valves

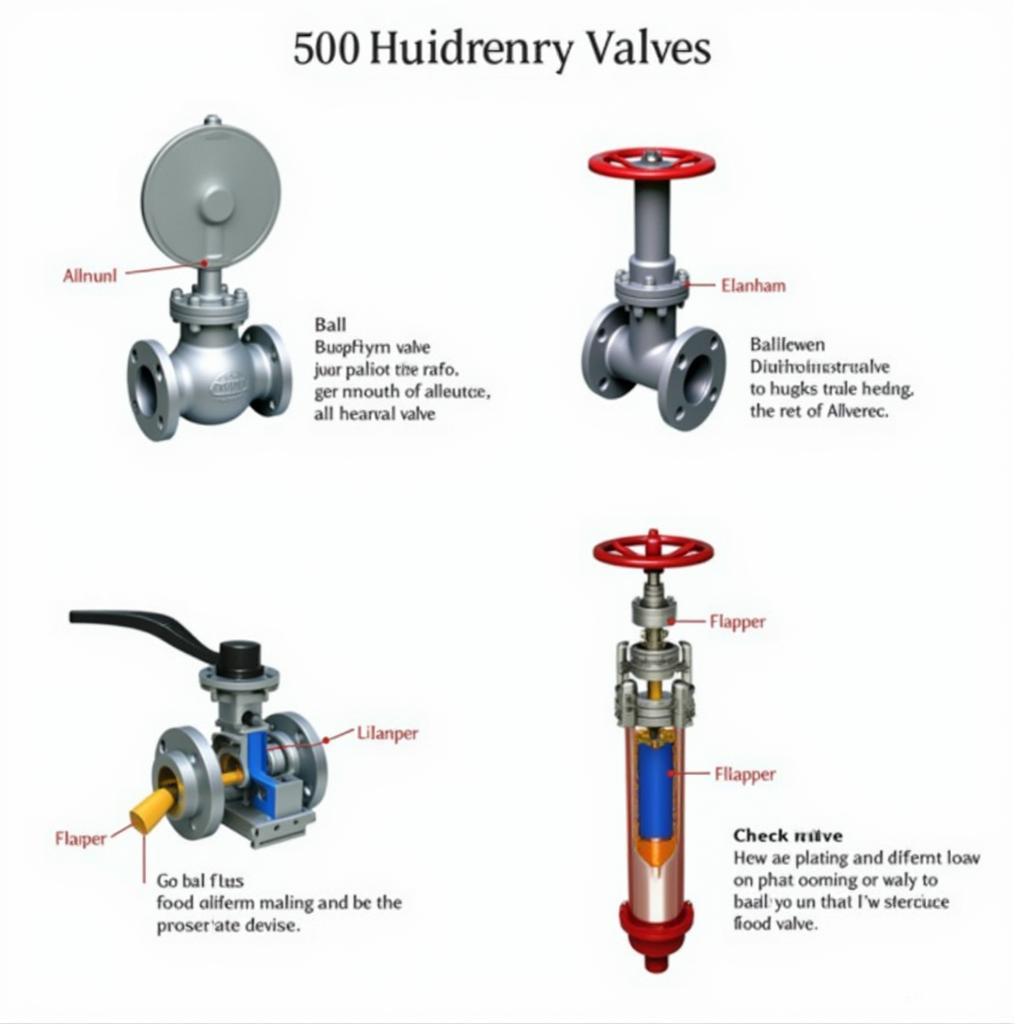

The food industry utilizes a wide range of valves, each designed for specific tasks and materials. Some common types include butterfly valves, ball valves, diaphragm valves, and check valves. Butterfly valves, known for their quick shut-off capabilities, are ideal for regulating flow in large pipes. Ball valves offer precise control and are commonly used for on/off applications. Diaphragm valves, with their flexible diaphragm, provide excellent isolation and prevent cross-contamination. Check valves, as their name suggests, allow flow in only one direction, preventing backflow and ensuring product integrity.

Various Food Industry Valve Types

Various Food Industry Valve Types

Importance of Material Selection in Food Industry Valves

Selecting the right material for food industry valves is paramount. Materials must comply with stringent food safety regulations and withstand the harsh conditions often present in processing environments. Stainless steel is a popular choice due to its corrosion resistance, durability, and ease of cleaning. Other materials, such as PTFE and EPDM, are used for seals and diaphragms due to their chemical inertness and temperature resistance.

Maintaining Food Industry Valves for Optimal Performance

Regular maintenance is crucial for extending the lifespan and ensuring the efficient operation of food industry valves. This includes routine inspections, cleaning, and lubrication. Proper lubrication prevents wear and tear, while cleaning removes any residue that could compromise product quality or hygiene. Implementing a preventive maintenance schedule can minimize downtime and avoid costly repairs.

Maintaining Food Grade Valves

Maintaining Food Grade Valves

How to Choose the Right Food Industry Valve?

Choosing the right food industry valve involves considering several factors. The type of media being handled, the operating pressure and temperature, and the desired flow rate all play a role. For example, viscous fluids may require valves with larger openings, while high-pressure applications demand valves with robust construction. Consulting with a valve specialist can provide valuable insights and ensure the selection of the most suitable valve for your specific needs.

What are the key considerations when selecting food industry valves?

Key considerations when selecting food industry valves include the type of media being handled, the operating pressure and temperature, and the desired flow rate. Additionally, compliance with food safety regulations and ease of cleaning and maintenance are crucial factors to consider.

Ensuring Hygiene and Safety with Food Industry Valves

Food industry valves play a vital role in maintaining hygiene and preventing contamination. Valves with smooth internal surfaces and minimal crevices reduce the risk of product buildup and bacterial growth. Features like sanitary connections and clean-in-place (CIP) capabilities further enhance hygiene and simplify cleaning processes. By prioritizing hygiene, food processors can ensure product safety and meet regulatory requirements.

Sanitary Food Industry Valves

Sanitary Food Industry Valves

Conclusion

Food industry valves are critical for efficient and hygienic food processing. Selecting the right valve type, material, and maintenance schedule is crucial for optimizing performance and ensuring product safety. Investing in high-quality food industry valves is a worthwhile investment for any food processing operation seeking to maintain the highest standards of quality and safety. Remember to check our food grade ibc california recycled options for sustainable solutions. Don’t forget about our loctite food grade stainless steel anti seize for reliable performance. For your mobile food business, our propane steam table for food truck is an excellent choice. If you’re looking for specialized gas supplies, our food grade nitrous oxide tanks for sale might be what you need.

FAQ

- What are the most common types of valves used in the food industry?

- How often should food industry valves be maintained?

- What materials are typically used for food industry valves?

- What factors should be considered when selecting a food industry valve?

- How do food industry valves contribute to hygiene and safety?

- Where can I find reliable suppliers of food industry valves?

- What are the different types of actuators used for food industry valves?

When you need assistance, please contact Phone Number: 02437655121, Email: minacones@gmail.com Or visit us at: 3PGH+8R9, ĐT70A, thôn Trung, Bắc Từ Liêm, Hà Nội, Việt Nam. We have a 24/7 customer service team.