Food Grade Water Pumps are essential for various applications, ensuring the safe and hygienic transfer of water for consumption or food processing. Whether you’re operating a food truck, setting up a mobile beverage cart, or need a reliable pump for your home brewing system, understanding the intricacies of food grade water pumps is crucial. This guide delves into the world of food grade water pumps, exploring their types, applications, and factors to consider when choosing the right one for your needs.

What Makes a Water Pump “Food Grade”?

Not all water pumps are created equal, especially when it comes to handling substances intended for consumption. Food grade water pumps are specifically designed and manufactured using materials that meet stringent safety standards. These materials, often stainless steel or specific food-grade plastics, prevent contamination, off-flavors, and potential health hazards.

Here’s a closer look at the key characteristics of food grade water pumps:

- Material Safety: They are constructed using materials compliant with FDA regulations for food contact. This ensures the pump’s components won’t leach harmful chemicals into the water.

- Corrosion Resistance: Food grade pumps are highly resistant to corrosion, a vital factor in maintaining water purity and extending the pump’s lifespan.

- Ease of Cleaning: Their design often incorporates smooth surfaces and minimal crevices, making them easy to clean and sanitize, a critical aspect of food safety.

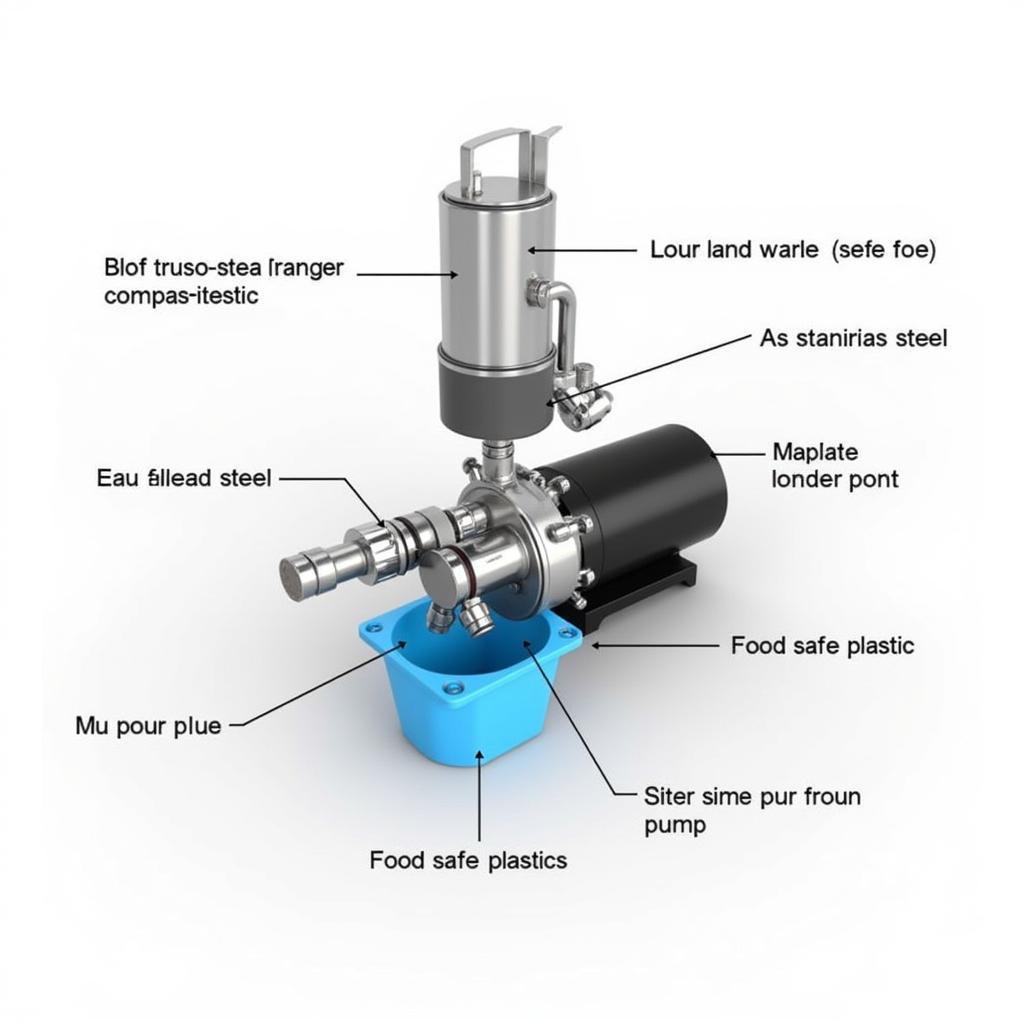

Food Grade Water Pump Components

Food Grade Water Pump Components

Exploring Different Types of Food Grade Water Pumps

Food grade water pumps come in various types, each suited for specific applications:

1. Centrifugal Pumps

Centrifugal pumps are a popular choice for high-flow applications. They use a rotating impeller to generate centrifugal force, propelling water through the pump. These pumps are known for their efficiency and ability to handle slightly viscous fluids.

Ideal for: Food processing plants, beverage dispensing systems.

2. Diaphragm Pumps

Diaphragm pumps utilize a reciprocating diaphragm to move fluids. They are known for their self-priming capabilities, making them suitable for applications where the pump isn’t constantly submerged.

Ideal for: Food trucks, mobile beverage carts, batch processing.

3. Gear Pumps

Gear pumps use interlocking gears to move fluids. They excel in handling viscous fluids like syrups or sauces and offer precise metering capabilities.

Ideal for: Food manufacturing, dosing systems for ingredients.

4. Peristaltic Pumps

Peristaltic pumps, also known as hose pumps, use rollers to squeeze a flexible tube. This design ensures the fluid only contacts the tube’s interior, making it ideal for sterile applications.

Ideal for: Pharmaceutical and biotech industries, delicate food products.

Choosing the Perfect Pump: Factors to Consider

Selecting the right food grade water pump requires careful consideration of your specific needs:

- Flow Rate and Pressure: Determine the required flow rate (gallons per minute) and pressure (PSI) based on your application.

- Fluid Viscosity: The thickness of the fluid you’ll be pumping influences the type of pump you need.

- Operating Conditions: Consider factors like temperature, suction lift, and discharge head.

- Certifications: Look for pumps certified by NSF, WRAS, or other relevant organizations, ensuring they meet food safety standards.

Food Grade Water Pump Maintenance: Keeping it Clean and Efficient

Proper maintenance is crucial for the longevity and performance of your food grade water pump:

- Regular Cleaning: Implement a regular cleaning schedule using food-safe sanitizers to prevent bacterial growth and maintain hygiene.

- Inspection: Regularly inspect the pump for wear and tear, paying close attention to seals, gaskets, and diaphragms.

- Lubrication: Follow the manufacturer’s recommendations for lubrication to ensure smooth operation and minimize friction.

Beyond the Basics: Applications of Food Grade Water Pumps

Food grade water pumps play a vital role in various industries and applications:

- Food and Beverage Processing: Transferring ingredients, filling containers, and maintaining hygiene.

- Restaurants and Food Service: Ensuring clean water supply for cooking, dishwashing, and beverage dispensing.

- Pharmaceutical and Biotech: Handling sensitive fluids and maintaining sterile environments.

- Home Brewing: Transferring wort, circulating cooling water, and maintaining consistent brewing processes.

Food Grade Water Pumps: A Worthy Investment for Food Safety

Investing in a high-quality food grade water pump is essential for any business or individual handling food or beverages. These pumps ensure product integrity, prevent contamination, and promote a safe and hygienic environment. By understanding the different types, applications, and maintenance requirements, you can make informed decisions when choosing and using food grade water pumps.

FAQs About Food Grade Water Pumps

1. What is the difference between a regular water pump and a food grade water pump?

While both pumps move water, food grade pumps use materials compliant with food safety regulations, ensuring they don’t leach harmful substances into the water.

2. How often should I clean my food grade water pump?

The cleaning frequency depends on usage and the type of fluids handled. However, a general rule is to clean the pump after each use or at least once a week for regular use.

3. Can I use a regular garden hose with my food grade water pump?

Using a regular garden hose is not recommended as it may not be made from food-safe materials and could contaminate the water. Always use food-grade hoses and fittings.

4. What should I look for when choosing a food grade water pump for my food truck?

Consider factors like flow rate, pressure, size, portability, and ease of cleaning. Opt for pumps with NSF or WRAS certification for peace of mind.

5. Where can I find replacement parts for my food grade water pump?

Contact the pump manufacturer or authorized dealers for genuine replacement parts that meet food safety standards.

6. What is the lifespan of a food grade water pump?

With proper maintenance and care, a high-quality food grade water pump can last for several years.

7. Can I repair a food grade water pump myself?

While minor repairs may be possible, it’s generally recommended to contact a qualified technician for repairs to ensure the pump continues to meet food safety standards.

Need More Information?

Looking for specific advice on food safe coating spray? Or perhaps you’re interested in learning about the importance of meat safety in food processor? We’ve got you covered! Explore our website for more insightful articles on food safety and related topics.

Ready to elevate your food handling practices? Contact us today! Our team of experts is here to answer your questions, provide personalized recommendations, and help you find the perfect food grade water pump for your needs. Call us at 02437655121, email us at minacones@gmail.com, or visit us at 3PGH+8R9, ĐT70A, thôn Trung, Bắc Từ Liêm, Hà Nội, Việt Nam. We offer 24/7 customer support for all your food safety needs.