Food Grade Gear Pumps play a vital role in the food and beverage industry, ensuring the safe and efficient transfer of various ingredients and products. These pumps are specifically designed to meet the stringent hygiene and safety standards required for food processing applications. This comprehensive guide delves into the intricacies of food grade gear pumps, providing valuable insights into their functionality, benefits, applications, and factors to consider when selecting the ideal pump for your specific needs.

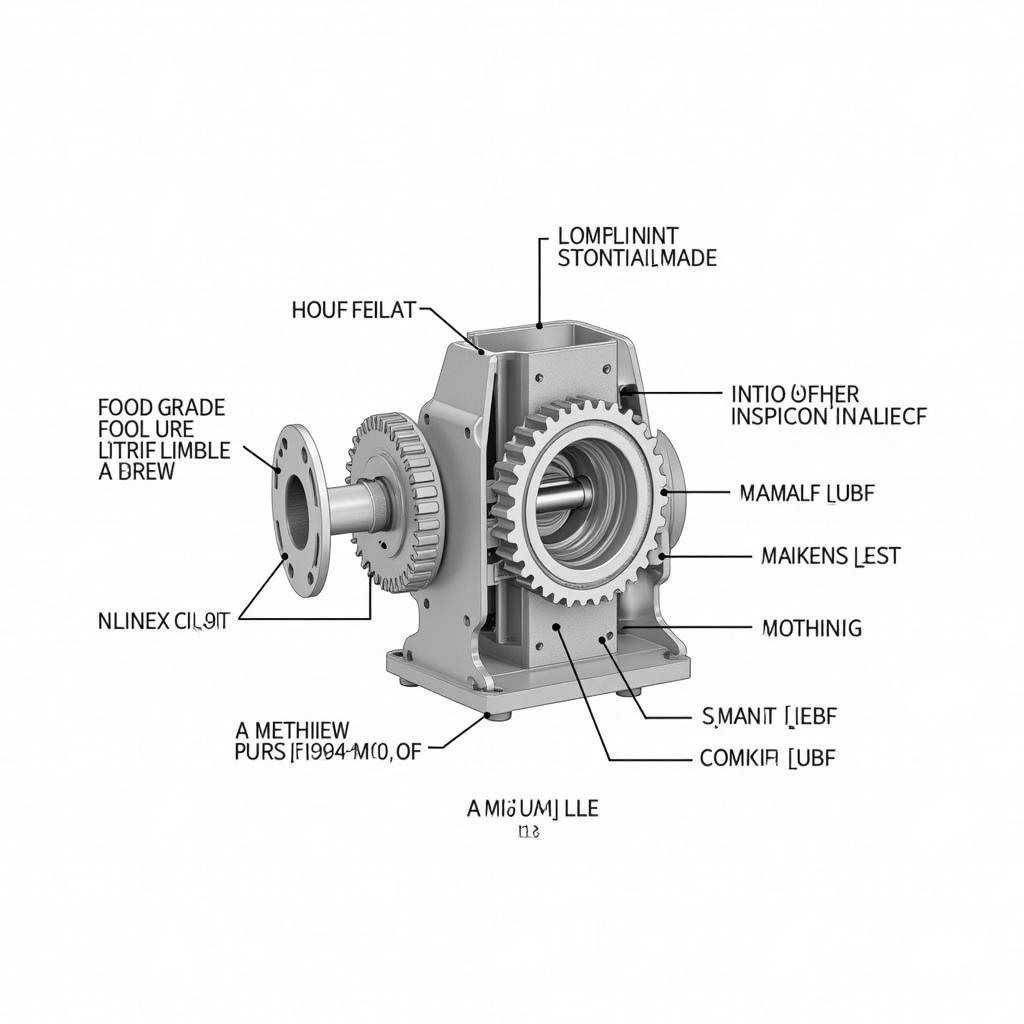

Food Grade Gear Pump Components

Food Grade Gear Pump Components

Understanding Food Grade Gear Pumps

Gear pumps are a type of positive displacement pump, meaning they deliver a fixed volume of fluid for each rotation of the gears. They consist of two meshing gears housed within a precisely machined casing. As the gears rotate, they create a suction force that draws fluid into the pump inlet. The fluid is then trapped between the gear teeth and the casing, transported around the pump, and discharged through the outlet.

What sets food grade gear pumps apart is their construction using materials that comply with strict food safety regulations. These materials, such as stainless steel and food-grade elastomers, are non-reactive, corrosion-resistant, and easy to clean, ensuring the integrity and safety of the food products being processed.

Advantages of Food Grade Gear Pumps in Food Processing

Food grade gear pumps offer several advantages that make them indispensable in various food processing applications:

- Gentle Product Handling: The rotating gears provide a smooth and pulsation-free flow, minimizing product damage and preserving the quality of delicate ingredients.

- High Viscosity Handling: Unlike centrifugal pumps, gear pumps excel at handling highly viscous fluids like honey, syrups, and chocolate, making them ideal for a wide range of food products.

- Accurate Metering and Dosing: The positive displacement nature of gear pumps allows for precise metering and dosing, ensuring consistent product quality and reducing waste.

- Hygienic Design and Easy Cleaning: Food grade gear pumps are designed with smooth surfaces, rounded corners, and minimal crevices to prevent product buildup and facilitate easy cleaning and sanitation.

Applications of Food Grade Gear Pumps

The versatility of food grade gear pumps makes them suitable for a wide range of applications in the food and beverage industry, including:

- Dairy Processing: Transferring milk, cream, yogurt, and cheese products.

- Beverage Production: Pumping syrups, juices, concentrates, and alcoholic beverages.

- Bakery and Confectionery: Dosing fillings, icings, and chocolate.

- Sauce and Condiment Manufacturing: Transferring ketchup, mayonnaise, mustard, and dressings.

- Meat and Poultry Processing: Pumping marinades, brines, and sauces.

Factors to Consider When Choosing a Food Grade Gear Pump

Selecting the right food grade gear pump for your specific application requires careful consideration of several factors:

- Flow Rate and Pressure Requirements: Determine the desired flow rate and pressure needed for your process.

- Fluid Viscosity and Temperature: Consider the viscosity and temperature range of the fluid being pumped.

- Material Compatibility: Ensure that the pump materials are compatible with the food product to prevent contamination or degradation.

- Cleaning and Maintenance Requirements: Choose a pump that is easy to clean, sanitize, and maintain to ensure food safety.

- Certifications and Standards: Look for pumps that meet relevant industry certifications and standards, such as 3-A Sanitary Standards and FDA regulations.

Maintaining Food Grade Gear Pumps

Proper maintenance is crucial for ensuring the longevity and performance of food grade gear pumps. Regular maintenance tasks include:

- Inspection and Lubrication: Regularly inspect the pump for any signs of wear and tear and lubricate moving parts according to manufacturer recommendations.

- Cleaning and Sanitation: Follow established cleaning and sanitation protocols to prevent product buildup and microbial contamination.

- Seal Replacement: Replace seals as needed to prevent leaks and maintain pump efficiency.

Conclusion

Food grade gear pumps are essential components in the food and beverage industry, ensuring the safe and efficient transfer of various food products. Understanding the different types, benefits, applications, and maintenance requirements of these pumps is crucial for selecting and operating them effectively. By adhering to industry standards and best practices, food processors can leverage the advantages of food grade gear pumps to optimize their operations and deliver high-quality food products to consumers.

FAQs

Q: What is the difference between a food grade gear pump and an industrial gear pump?

A: Food grade gear pumps are specifically designed and constructed using materials that meet strict hygiene and safety standards for food processing, while industrial gear pumps may not adhere to these stringent requirements.

Q: Can food grade gear pumps handle abrasive fluids?

A: While food grade gear pumps are suitable for a wide range of fluids, they are not ideal for highly abrasive materials. Consult with a pump expert to determine the best pump type for abrasive fluids.

Q: How often should I clean and sanitize my food grade gear pump?

A: Cleaning and sanitation frequency depends on the specific application and product being pumped. It is recommended to follow established cleaning protocols and consult with manufacturer guidelines.

Q: What are some common signs of wear and tear in food grade gear pumps?

A: Common signs include leaks, reduced flow rate, unusual noises, and excessive vibration.

Q: Where can I find reputable suppliers of food grade gear pumps?

A: Look for established pump manufacturers and distributors specializing in food processing equipment.

Need Help Choosing the Right Food Grade Gear Pump?

Contact our team of experts at Mina Cones Food today! Call us at 02437655121, email us at minacones@gmail.com, or visit our office located at 3PGH+8R9, ĐT70A, thôn Trung, Bắc Từ Liêm, Hà Nội, Việt Nam. We’re available 24/7 to assist you with all your food processing equipment needs.