Custom Food Processing Equipment is revolutionizing the food industry, offering tailored solutions for unique production needs. From small artisanal producers to large-scale manufacturers, businesses are recognizing the benefits of investing in equipment designed specifically for their processes. This article explores the world of custom food processing equipment, from understanding its advantages to navigating the design and implementation process. mouli food mill

Why Choose Custom Food Processing Equipment?

Custom-designed equipment addresses specific challenges and opportunities within the food processing industry. Off-the-shelf solutions often fall short when dealing with unique product characteristics, production volumes, or space constraints. Choosing custom food processing equipment allows businesses to optimize their operations, enhance product quality, and improve overall efficiency. For instance, a small-batch jam producer might require a custom-designed filling system to handle delicate fruit preserves, while a large-scale bakery could benefit from an automated dough mixing and proofing system tailored to their specific recipes and output.

Benefits of Customization

- Improved Efficiency: Custom equipment streamlines processes, reducing manual labor and minimizing downtime.

- Enhanced Product Quality: Tailored designs ensure consistent product quality and minimize waste.

- Increased Throughput: Optimized equipment maximizes production capacity and meets growing demand.

- Space Optimization: Custom solutions are designed to fit existing facility layouts, saving valuable floor space.

- Integration with Existing Systems: Seamless integration with current production lines ensures smooth operations.

Custom Food Processing Equipment Design Process

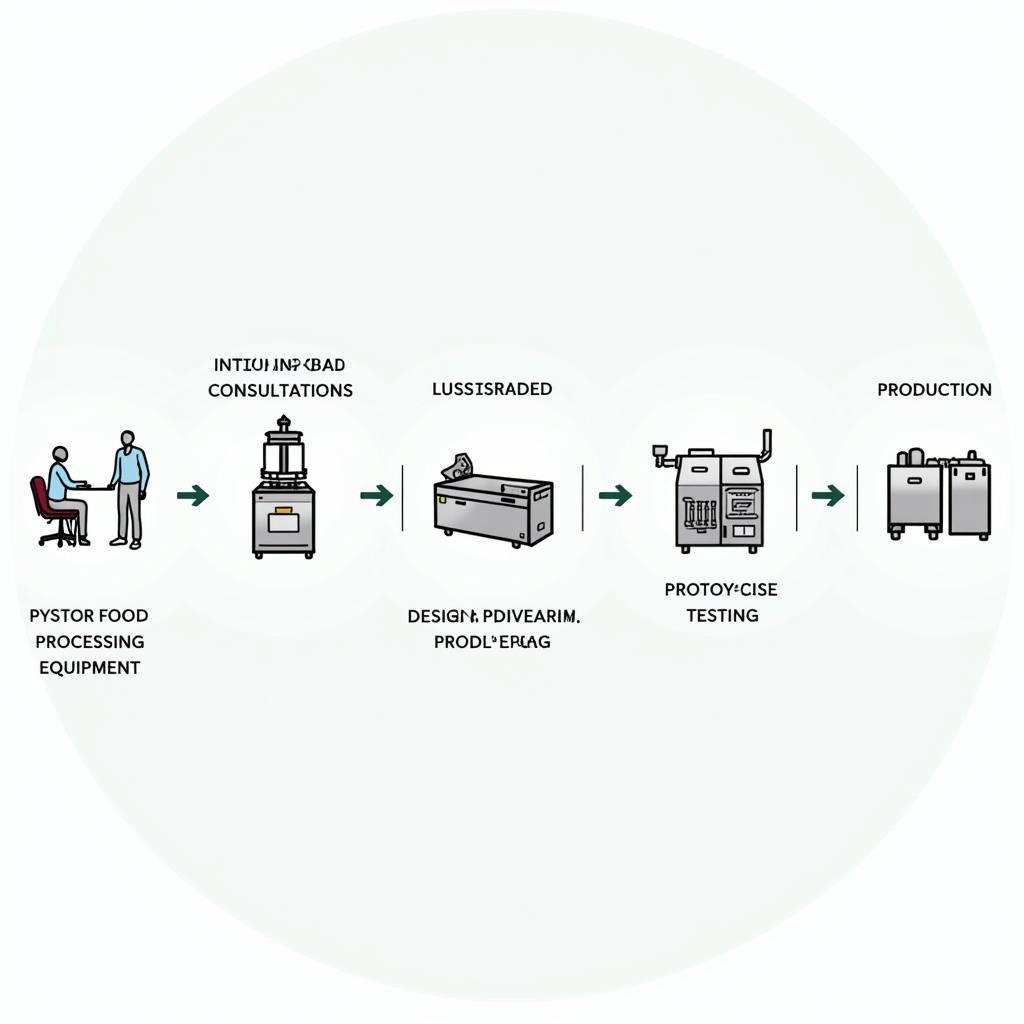

Custom Food Processing Equipment Design Process

The Custom Design Process

The process of designing custom food processing equipment involves a collaborative approach between the client and the equipment manufacturer. Clear communication and a thorough understanding of the client’s needs are crucial for a successful outcome.

Key Steps in the Design Process

- Initial Consultation: Defining project scope, objectives, and budget.

- Needs Assessment: Analyzing existing processes and identifying areas for improvement.

- Conceptual Design: Developing initial designs and specifications based on client requirements.

- Detailed Engineering: Creating comprehensive engineering drawings and specifications.

- Prototyping and Testing: Building and testing prototypes to ensure functionality and performance.

- Fabrication and Installation: Manufacturing the final equipment and installing it at the client’s facility.

- Training and Support: Providing comprehensive training and ongoing support to ensure smooth operation.

What are the typical timelines for custom equipment projects? Project timelines vary depending on the complexity of the equipment and the specific requirements of the client. However, most projects typically span several months from initial consultation to final installation.

Selecting the Right Manufacturer

Choosing the right manufacturer is paramount to the success of a custom food processing equipment project. Expertise, experience, and a proven track record are essential factors to consider.

Key Considerations When Choosing a Manufacturer:

- Experience and Expertise: Look for manufacturers specializing in the specific type of equipment required.

- Engineering Capabilities: Ensure the manufacturer has the necessary engineering expertise and resources.

- Project Management: A strong project management approach is crucial for timely and efficient execution.

- Quality Control: Stringent quality control measures ensure the equipment meets the highest standards.

- After-Sales Service and Support: Reliable after-sales service and support minimize downtime and maximize equipment lifespan.

Choosing a Qualified Food Processing Equipment Manufacturer

Choosing a Qualified Food Processing Equipment Manufacturer

“Investing in custom food processing equipment is a strategic decision that can significantly impact a company’s bottom line,” says John Smith, Senior Food Processing Engineer at Acme Food Solutions. “By optimizing processes and improving efficiency, custom equipment can lead to increased profitability and a competitive advantage in the marketplace.”

Maintaining Custom Food Processing Equipment

Proper maintenance is essential for maximizing the lifespan and performance of custom food processing equipment. Regular inspections, cleaning, and preventative maintenance are crucial to prevent breakdowns and ensure optimal operation.

“Regular preventative maintenance is key to minimizing downtime and extending the life of your custom equipment,” advises Jane Doe, Food Safety Consultant at FoodSafe Solutions. “A well-maintained machine not only ensures consistent product quality but also reduces the risk of costly repairs and production delays.”

nsf h1 nlgi 2 food safe grease

Conclusion

Custom food processing equipment offers a powerful solution for businesses seeking to optimize their operations and gain a competitive edge. By partnering with experienced manufacturers and following a structured design process, companies can realize the full potential of custom equipment and achieve their production goals. Investing in custom food processing equipment is a commitment to efficiency, quality, and long-term success in the dynamic food industry. Remember to prioritize your specific needs and collaborate closely with your chosen manufacturer to create a solution that perfectly aligns with your business objectives.

is gluten free food kosher for passover

Khi cần hỗ trợ hãy liên hệ Số Điện Thoại: 02437655121, Email: minacones@gmail.com Hoặc đến địa chỉ: 3PGH+8R9, ĐT70A, thôn Trung, Bắc Từ Liêm, Hà Nội, Việt Nam. Chúng tôi có đội ngũ chăm sóc khách hàng 24/7.