Belt conveyor systems have revolutionized the food processing and handling industry, offering a versatile and efficient way to transport ingredients and finished products. From small bakeries to large-scale manufacturing plants, these systems ensure a smooth and hygienic flow of food items throughout various stages of production.

A stainless steel belt conveyor system transporting fresh produce in a food processing facility

A stainless steel belt conveyor system transporting fresh produce in a food processing facility

Why Choose Belt Conveyors for Food Handling?

The food industry demands strict hygiene and safety standards, and belt conveyor systems are designed to meet these requirements head-on. Constructed from food-grade materials like stainless steel, these conveyors are resistant to corrosion, bacteria growth, and the harsh cleaning agents used in food processing environments.

But the benefits extend beyond hygiene:

- Improved Efficiency: Belt conveyors automate the movement of food items, reducing manual handling and boosting overall productivity. This translates to faster processing times and increased output.

- Versatility in Design: Belt conveyors come in a variety of sizes, configurations, and materials. This flexibility allows for customization to suit specific applications, whether it’s transporting delicate pastries or heavy crates of ingredients.

- Gentle Handling: The continuous and controlled movement of a belt conveyor minimizes product damage, a crucial factor when handling fragile food items like fruits, vegetables, and baked goods.

- Enhanced Workplace Safety: By automating tasks and reducing manual lifting, belt conveyors contribute to a safer working environment for employees.

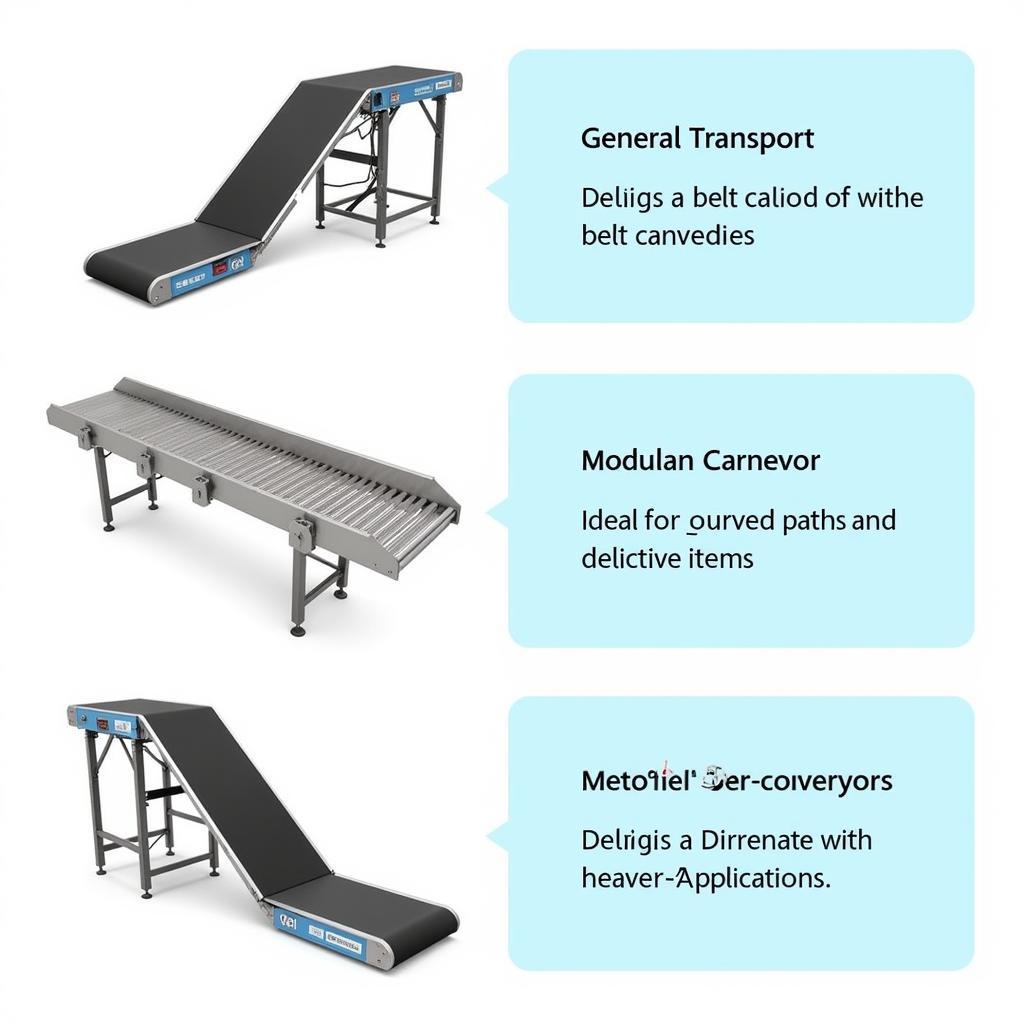

Various belt conveyor designs used in food processing – flat belt, modular belt, and cleated belt conveyors

Various belt conveyor designs used in food processing – flat belt, modular belt, and cleated belt conveyors

Types of Belt Conveyors Used in the Food Industry

The diverse nature of food production calls for specialized equipment. Let’s explore some common types of belt conveyors found in the food industry:

- Flat Belt Conveyors: These workhorses are ideal for transporting a wide range of food items over short to medium distances. Their simple design and ease of cleaning make them a popular choice.

- Modular Belt Conveyors: Constructed from interlocking plastic modules, these conveyors offer excellent flexibility for navigating curves and inclines. They are often preferred for handling delicate products and those requiring washing or draining.

- Cleated Belt Conveyors: Equipped with cleats or scoops attached to the belt surface, these conveyors excel at transporting bulk materials like grains, powders, and frozen foods, even at steep angles.

- Specialty Belt Conveyors: Beyond these common types, there are specialized conveyors designed for specific tasks, such as metal detection conveyors for ensuring food safety and accumulating conveyors for creating buffer zones in the production line.

Choosing the Right Belt Conveyor System

Selecting the optimal belt conveyor system for your food handling needs is crucial. Factors to consider include:

- Throughput Requirements: How much product needs to be moved per hour?

- Product Characteristics: What is the size, weight, and fragility of the items being conveyed?

- Production Environment: Is the environment wet, dry, hot, or cold?

- Cleaning and Sanitation Requirements: What are the specific hygiene standards for your facility?

“Investing in a well-designed belt conveyor system tailored to your specific needs is an investment in the efficiency, hygiene, and overall success of your food processing operation,” says Emily Carter, a leading food safety consultant. “By carefully considering your production requirements and working with experienced conveyor system manufacturers, you can optimize your processes and ensure the highest standards of food safety.”

Maintaining Your Belt Conveyor System

To ensure longevity and optimal performance, regular maintenance of your belt conveyor system is essential:

- Daily Inspections: Check the belt for any signs of wear and tear, debris, or misalignment.

- Regular Cleaning: Follow a strict cleaning schedule using food-grade sanitizers to remove any food residue and prevent bacterial growth.

- Lubrication: Properly lubricate moving parts to reduce friction and extend the lifespan of components.

- Scheduled Maintenance: Implement a preventative maintenance program that includes regular inspections by qualified technicians to identify and address potential issues before they escalate.

A technician in a hairnet and gloves meticulously inspecting a food-grade belt conveyor system

A technician in a hairnet and gloves meticulously inspecting a food-grade belt conveyor system

Conclusion

Belt conveyor systems have become an indispensable part of the modern food industry, facilitating efficient, hygienic, and safe food handling practices. By understanding the different types of systems available and carefully selecting one that aligns with your specific needs, you can streamline your operations, enhance product quality, and ensure the highest standards of food safety. When combined with a proactive maintenance program, your belt conveyor system will continue to be a reliable workhorse in your food processing operation for years to come.

FAQs about Belt Conveyor Food Systems

1. What types of food can be transported on a belt conveyor?

Belt conveyors can be used to transport a wide variety of food items, including fresh produce, baked goods, meat and poultry, seafood, packaged foods, and more.

2. How do I clean a belt conveyor used for food handling?

Cleaning procedures will vary depending on the type of food being processed. However, general guidelines include using food-grade sanitizers, disassembling certain parts for thorough cleaning, and allowing the conveyor to dry completely before resuming operation.

3. How much does a belt conveyor system for food handling cost?

The cost of a belt conveyor system can vary greatly depending on factors such as size, length, material, features, and installation. It’s best to contact a conveyor system manufacturer for a customized quote.

4. How long do belt conveyors for food handling last?

With proper maintenance and care, a well-maintained belt conveyor system can last for many years. Regular inspections, cleaning, and lubrication are crucial for extending the lifespan of the system.

5. Can I add features to my belt conveyor system after it’s been installed?

In many cases, it’s possible to add features or modify existing belt conveyor systems to accommodate changing production needs. Consult with a conveyor system specialist to discuss your specific requirements.

Need Assistance with Belt Conveyors for Your Food Business?

Contact Mina Cones Food today! Our team of experts can help you design and implement the perfect belt conveyor system to optimize your food handling processes. Reach us at Phone Number: 02437655121, Email: minacones@gmail.com, or visit our office at 3PGH+8R9, ĐT70A, thôn Trung, Bắc Từ Liêm, Hà Nội, Việt Nam. Our customer service team is available 24/7 to assist you.