Food Grade Hydraulic Oil is essential for maintaining the safety and efficiency of machinery used in food processing environments. It’s crucial to understand its properties and applications to prevent contamination and ensure smooth operations. This article will explore the intricacies of food grade hydraulic oil, its benefits, and why choosing the right type is paramount.

Understanding Food Grade Hydraulic Oil

Hydraulic oil plays a vital role in powering various equipment in food processing plants. However, conventional hydraulic oils pose a significant contamination risk. Leakage or accidental contact can compromise food safety. This is where food grade hydraulic oil comes into play. These specially formulated oils are designed to minimize the risk of food contamination in case of incidental contact.

What Makes Hydraulic Oil “Food Grade”?

Food grade hydraulic oils are typically based on highly refined base oils and fortified with additives that meet stringent safety standards. These oils are categorized by organizations like the NSF (National Sanitation Foundation) based on their level of incidental food contact allowance. H1 lubricants, for example, are suitable for use where there is a possibility of incidental food contact, while H2 lubricants are for equipment where no food contact is expected.

Benefits of Using Food Grade Hydraulic Oil

Choosing food grade hydraulic oil isn’t just about compliance; it’s about prioritizing safety and operational efficiency.

- Enhanced Food Safety: The primary benefit is the reduced risk of contamination, protecting consumers and the brand’s reputation.

- Improved Equipment Longevity: These oils offer excellent lubrication properties, extending the lifespan of machinery and reducing maintenance costs.

- Reduced Downtime: Reliable lubrication minimizes unexpected breakdowns, keeping production lines running smoothly.

- Peace of Mind: Knowing your equipment operates with safe lubricants provides peace of mind and allows you to focus on quality food production.

Food Grade Hydraulic Oil Applications in Food Processing Plants

Food Grade Hydraulic Oil Applications in Food Processing Plants

Choosing the Right Food Grade Hydraulic Oil

Selecting the appropriate food grade hydraulic oil depends on several factors, including the type of equipment, operating temperature, and the level of potential food contact.

Key Considerations When Selecting an Oil:

- Viscosity: The oil’s thickness is crucial for proper lubrication and efficient power transmission.

- Oxidation Stability: Resistance to degradation over time ensures consistent performance and extended oil life.

- Anti-wear Properties: Additives protect equipment components from wear and tear, reducing maintenance needs.

- NSF Certification: Verify the oil’s NSF rating (H1, H2, or H3) to ensure it meets the required safety standards for your application.

Maintaining Food Grade Hydraulic Systems

Regular maintenance is essential to ensure the continued effectiveness of food grade hydraulic oil.

- Regular Oil Analysis: Monitoring the oil’s condition helps identify potential problems early on, preventing costly repairs.

- Proper Filtration: Effective filtration removes contaminants and extends the oil’s lifespan.

- Leak Prevention: Regular inspections and prompt repairs of leaks minimize the risk of contamination and oil loss.

Maintaining Hydraulic Systems in Food Processing

Maintaining Hydraulic Systems in Food Processing

“Regular maintenance and the use of high-quality food grade hydraulic oil are crucial for maintaining a safe and efficient food processing environment,” says John Miller, a seasoned food safety consultant with over 20 years of experience. “Investing in the right lubricants not only protects consumers but also contributes to a more sustainable and profitable operation.”

Common Misconceptions about Food Grade Hydraulic Oil

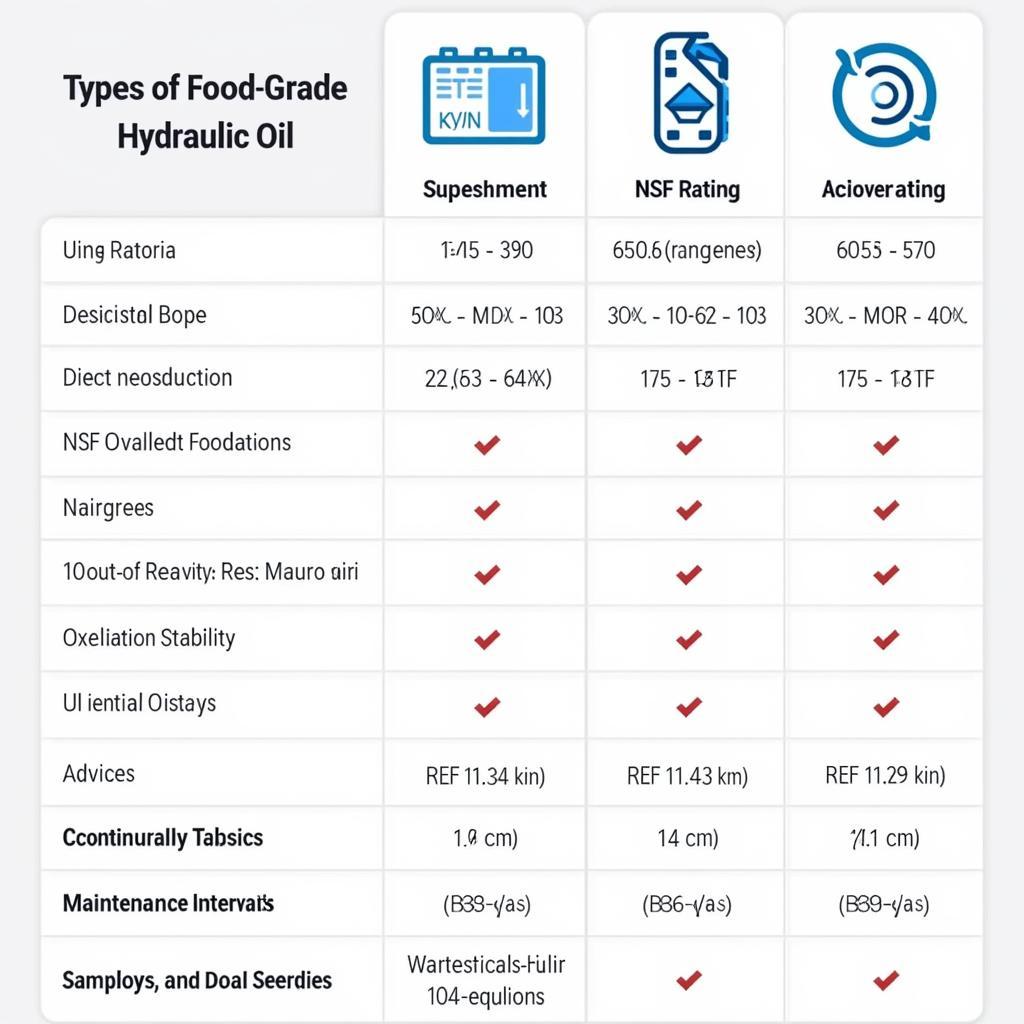

One common misconception is that all food grade oils are the same. This is simply not true. Different formulations offer varying levels of performance and protection. Another myth is that food grade oils are significantly more expensive than conventional hydraulic oils. While there might be a slight price difference, the long-term benefits in terms of safety, equipment longevity, and reduced downtime far outweigh the initial cost.

Comparing Different Types of Food Grade Hydraulic Oil

Comparing Different Types of Food Grade Hydraulic Oil

Conclusion

Food grade hydraulic oil is a critical component in ensuring the safety and efficiency of food processing operations. Choosing the right oil and implementing a robust maintenance program are essential for protecting consumers, extending equipment life, and minimizing downtime. By understanding the intricacies of food grade hydraulic oils, food processors can make informed decisions that contribute to a safer, more efficient, and ultimately, more profitable operation. Remember, prioritizing food safety is not just a regulatory requirement; it’s a commitment to quality and consumer well-being.

FAQs

- What is the difference between H1 and H2 food grade lubricants? H1 lubricants are for incidental food contact, while H2 are for where no food contact is anticipated.

- How often should I change my food grade hydraulic oil? Oil change frequency depends on factors like operating conditions and oil analysis results. Consult your equipment manufacturer or oil supplier for specific recommendations.

- Can I use regular hydraulic oil in food processing equipment? No, regular hydraulic oil poses a contamination risk and is not suitable for food processing applications.

- What are the consequences of using the wrong type of food grade hydraulic oil? Using the incorrect oil can lead to equipment damage, reduced efficiency, and potential food contamination.

- Where can I purchase food grade hydraulic oil? Food grade hydraulic oil can be purchased from specialized lubricant suppliers and distributors.

- What are some common brands of food grade hydraulic oil? There are several reputable brands offering food grade hydraulic oils, each with specific formulations and certifications. Research and compare to find the best fit for your needs.

- How can I ensure the authenticity of the food grade hydraulic oil I purchase? Always check for NSF certification and verify the supplier’s credentials.

Further Exploration

Explore our other articles on food safety and equipment maintenance for more valuable insights. Learn about best practices for cleaning and sanitizing food processing equipment and discover the latest advancements in lubrication technology.

Need Support? Contact us at Phone Number: 02437655121, Email: minacones@gmail.com Or visit us at: 3PGH+8R9, ĐT70A, thôn Trung, Bắc Từ Liêm, Hà Nội, Việt Nam. We have a 24/7 customer service team.