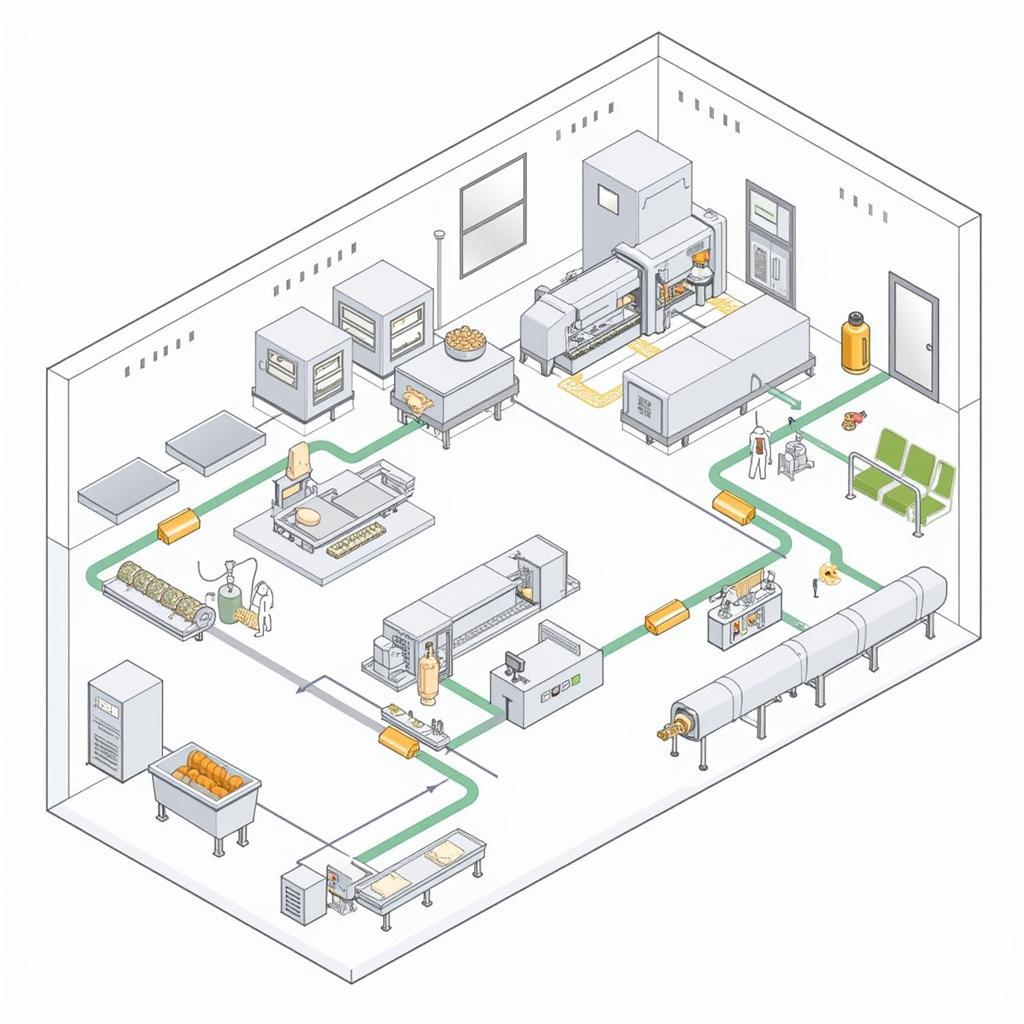

Floor Plan Food Processing Plant Design And Layout is crucial for efficient operations, ensuring food safety, and maximizing profitability. A well-designed layout optimizes workflow, minimizes contamination risks, and facilitates compliance with regulations. From raw material reception to finished product storage, every element must be strategically placed to create a seamless and hygienic production environment.

Key Considerations for Food Processing Plant Layout

Designing a food processing facility requires meticulous planning and attention to detail. Here are some key factors to consider:

- Workflow Optimization: The layout should facilitate a logical flow of materials and personnel, minimizing cross-contamination and maximizing efficiency. Imagine a smoothly running production line, where each step seamlessly transitions to the next. This not only saves time and resources but also improves overall productivity.

- Hygiene and Sanitation: Food safety is paramount. The design must incorporate easy-to-clean surfaces, adequate drainage, and proper ventilation to prevent bacterial growth and contamination. Think stainless steel surfaces, food safe flooring, and specialized cleaning systems to ensure the highest standards of hygiene.

- Compliance with Regulations: Meeting local and international food safety standards is essential. The layout should facilitate inspection and ensure compliance with regulations like HACCP and GMP.

- Flexibility and Scalability: The design should be adaptable to future expansion and changes in product lines. A modular design can accommodate growth and evolving needs without requiring major renovations.

Food Processing Plant Workflow Optimization

Food Processing Plant Workflow Optimization

Optimizing Space Utilization in Your Food Processing Plant

Space is a premium in any food processing facility. Maximizing space utilization is key to efficiency and profitability. Consider these strategies:

- Vertical Space: Utilize vertical space with multi-tiered storage and processing equipment. This maximizes floor space and improves accessibility. Imagine vertical conveyors transporting ingredients between different levels, freeing up valuable floor space for other essential operations.

- Modular Design: Employ modular equipment and layouts for flexibility and adaptability. This allows for easy reconfiguration and expansion as needed.

- Equipment Placement: Strategically place equipment to minimize movement and optimize workflow. Consider the proximity of related processes and the flow of materials.

What are the essential elements of a food processing plant floor plan?

A comprehensive floor plan includes areas for receiving raw materials, processing, packaging, storage, quality control, and administrative offices. It also considers utilities, waste disposal, and employee facilities.

“A well-designed layout considers not only the present needs but also anticipates future growth and changes in the industry. This forward-thinking approach ensures long-term viability and success.” – Dr. Amelia Hernandez, Food Processing Engineer

Food Safe Flooring: A Critical Component of Food Processing Plant Design

Food safe flooring plays a vital role in maintaining hygiene and preventing contamination. Food safe flooring must be durable, slip-resistant, and easy to clean. It should also be resistant to chemicals and temperature fluctuations. This type of flooring helps to prevent the growth of bacteria and other harmful microorganisms, ensuring the safety and quality of the final product.

How do you choose the right flooring for your food processing plant?

Factors to consider include the type of processing, the level of traffic, and the cleaning regime. Different areas may require different flooring solutions. For example, wet processing areas need flooring that can withstand moisture and prevent slips, while dry storage areas require flooring that is durable and easy to clean.

Food Safe Flooring in a Processing Plant

Food Safe Flooring in a Processing Plant

“Investing in high-quality food safe flooring is an investment in the long-term success of your food processing business. It protects your products, your employees, and your bottom line.” – John Miller, Food Safety Consultant

Conclusion

Floor plan food processing plant design and layout requires a comprehensive approach considering workflow, hygiene, compliance, and future scalability. A well-designed facility ensures efficient operations, maximizes food safety, and contributes to the overall success of the business.

FAQ

- What is the importance of workflow in food processing plant design?

- What are the key regulations to consider when designing a food processing plant?

- How can I maximize space utilization in my facility?

- What are the different types of food safe flooring available?

- How do I choose the right flooring for my specific needs?

- What are the benefits of a modular design?

- How can I ensure my plant design is adaptable to future changes?

When you need assistance, please contact us at Phone Number: 02437655121, Email: minacones@gmail.com or visit us at 3PGH+8R9, ĐT70A, thôn Trung, Bắc Từ Liêm, Hà Nội, Việt Nam. We have a 24/7 customer service team.