Industrial Food Mixer Machines are essential for any large-scale food processing operation. They allow for efficient and consistent mixing of ingredients, crucial for producing high-quality food products. Choosing the right mixer can significantly impact your production line, so understanding the nuances of these powerful machines is essential. Let’s delve into the world of industrial food mixers and explore everything you need to know. You can find valuable information on related food processing equipment, such as pet food processing equipment, at our site.

Types of Industrial Food Mixer Machines

Industrial food mixers come in various shapes and sizes, each designed for a specific purpose. Choosing the right type depends on the ingredients, desired consistency, and volume of your product.

Ribbon Blenders

Ribbon blenders are ideal for dry ingredients, powders, and granules. Their horizontal design and ribbon-like agitators ensure thorough mixing. These machines excel at creating a uniform blend in a short amount of time.

Sigma Blade Mixers

Sigma blade mixers are heavy-duty machines designed for thicker, more viscous materials like dough and pastes. Their powerful, intersecting blades provide high shear mixing, resulting in a smooth and homogeneous product.

Planetary Mixers

Planetary mixers offer versatility for a wide range of mixing tasks. Their rotating agitator moves in a planetary motion, reaching all corners of the bowl. These mixers are commonly used for whipping, beating, and mixing ingredients of varying viscosities.

Vertical Cutter Mixers

Vertical cutter mixers are specifically designed for challenging mixing tasks, such as emulsifying and homogenizing. They utilize high-speed blades to chop and blend ingredients, creating a fine and uniform texture.

After this section, you might find our resources on foaming machine food industry helpful for your research.

Different Types of Industrial Food Mixers

Different Types of Industrial Food Mixers

Choosing the Right Industrial Food Mixer Machine

Selecting the right industrial food mixer machine requires careful consideration of several factors.

Capacity

Determining the appropriate capacity is crucial for meeting production demands. Consider your batch sizes and projected growth when choosing the mixer’s volume.

Mixing Action

Different mixers offer different mixing actions, from gentle blending to high-shear mixing. The required mixing action depends on the desired consistency of the final product.

Material Construction

The material construction of the mixer should be compatible with the ingredients being processed. Stainless steel is a common choice due to its durability and hygiene.

Cleaning and Maintenance

Ease of cleaning and maintenance is vital for ensuring food safety and minimizing downtime. Look for mixers with easy-to-disassemble parts and sanitary designs.

Maintaining Your Industrial Food Mixer Machine

Proper maintenance is crucial for maximizing the lifespan and performance of your industrial food mixer machine.

Regular Cleaning

Regular cleaning prevents the buildup of food residue, which can lead to contamination and reduced efficiency.

Lubrication

Proper lubrication ensures smooth operation and reduces wear and tear on moving parts. Choosing the right food grade lube is crucial for food safety. You can explore more information about food-grade lubricants on our dedicated page.

Inspections

Regular inspections can identify potential problems early on, preventing costly repairs and downtime.

“Regular maintenance is the key to longevity and optimal performance,” says Amelia Hernandez, a seasoned food processing consultant. “Investing in preventative measures saves you money in the long run.”

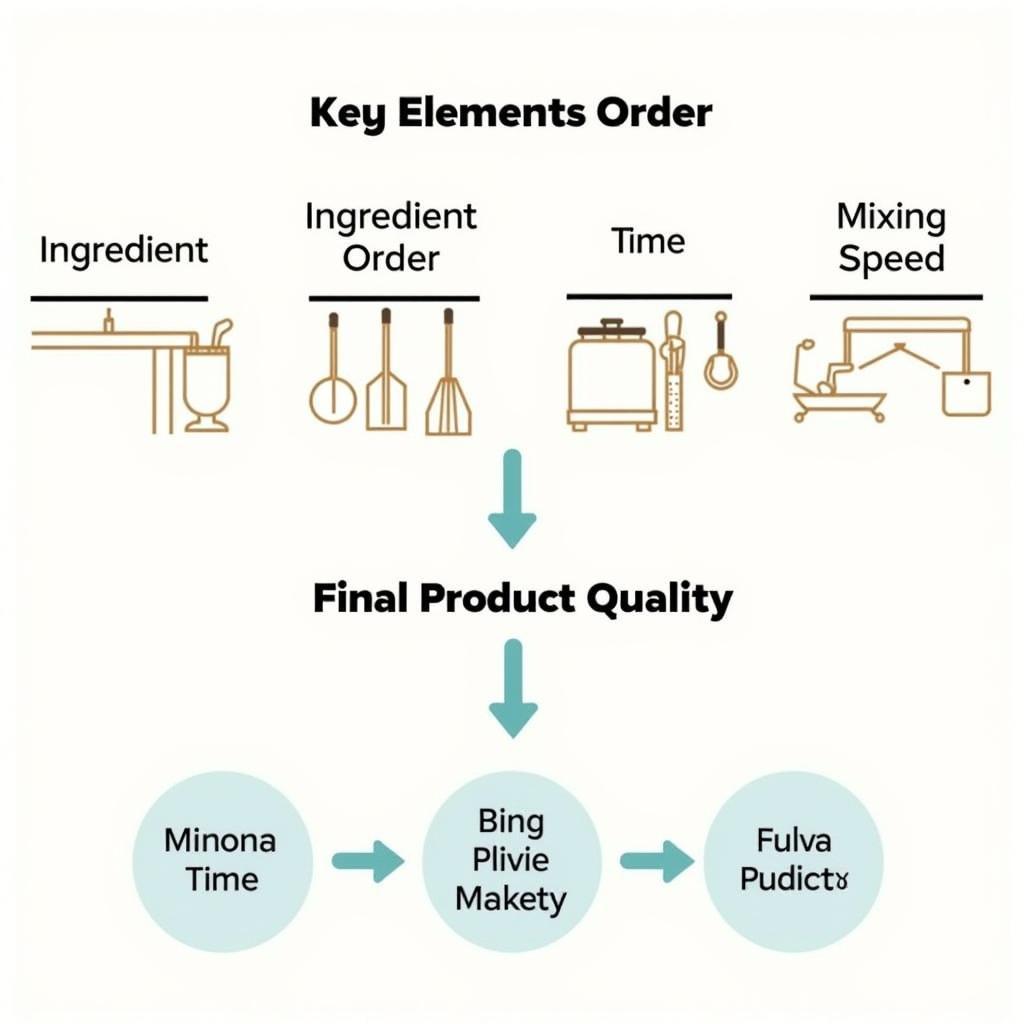

Optimizing Your Mixing Process

Optimizing your mixing process involves understanding the nuances of your ingredients and adjusting the mixing parameters accordingly.

Ingredient Order

The order in which ingredients are added can impact the final product’s quality and consistency.

Mixing Time

The optimal mixing time depends on the ingredients and desired consistency. Overmixing can lead to undesirable results, while undermixing can result in an uneven blend.

Mixing Speed

The mixing speed should be adjusted based on the ingredients and mixing action. Too high a speed can damage ingredients, while too low a speed may not achieve the desired mixing effect.

Tips for Optimizing the Food Mixing Process with an Industrial Mixer

Tips for Optimizing the Food Mixing Process with an Industrial Mixer

“Understanding the interplay between ingredients and mixing parameters is crucial for achieving optimal results,” notes David Chen, a leading food scientist. “Experimentation and careful observation are essential for refining your process.” You can also learn about evaluating food processing equipment via our food processing equipment appraisal page.

Conclusion

Investing in a high-quality industrial food mixer machine is essential for any large-scale food processing operation. By understanding the different types of mixers, choosing the right model for your needs, and implementing proper maintenance procedures, you can ensure efficient and consistent mixing, ultimately leading to superior food products. Remember that the right industrial food mixer machine is an investment in the quality and success of your business.

FAQ

- What is the most versatile type of industrial food mixer? Planetary mixers are often considered the most versatile due to their ability to handle a variety of mixing tasks.

- How often should I clean my industrial food mixer? Cleaning frequency depends on usage, but daily cleaning is recommended for most applications.

- What is the importance of using food-grade lubricants? Food-grade lubricants prevent contamination and ensure the safety of the final product.

- How do I choose the right capacity for my mixer? Consider your batch sizes and future production needs.

- What are the signs of a malfunctioning mixer? Unusual noises, vibrations, or inconsistent mixing are signs of potential problems.

- Where can I find more information on food and machines? Our website’s food and machines section provides a wealth of information on this topic.

- What factors should I consider when purchasing a used industrial mixer? Condition, age, previous usage, and maintenance records are important factors to consider.

For further assistance, please contact us at Phone Number: 02437655121, Email: [email protected] or visit our address: 3PGH+8R9, ĐT70A, thôn Trung, Bắc Từ Liêm, Hà Nội, Việt Nam. We have a 24/7 customer support team.