Food Processing Plant Construction is a complex undertaking, requiring careful planning, meticulous execution, and a deep understanding of the food industry. From initial concept to final commissioning, each stage plays a vital role in creating a facility that meets stringent hygiene standards, optimizes production efficiency, and delivers high-quality food products. This guide will delve into the key aspects of building a successful food processing plant, offering insights into best practices and essential considerations for every step of the process.

Designing for Success: The Blueprint of Your Food Processing Plant

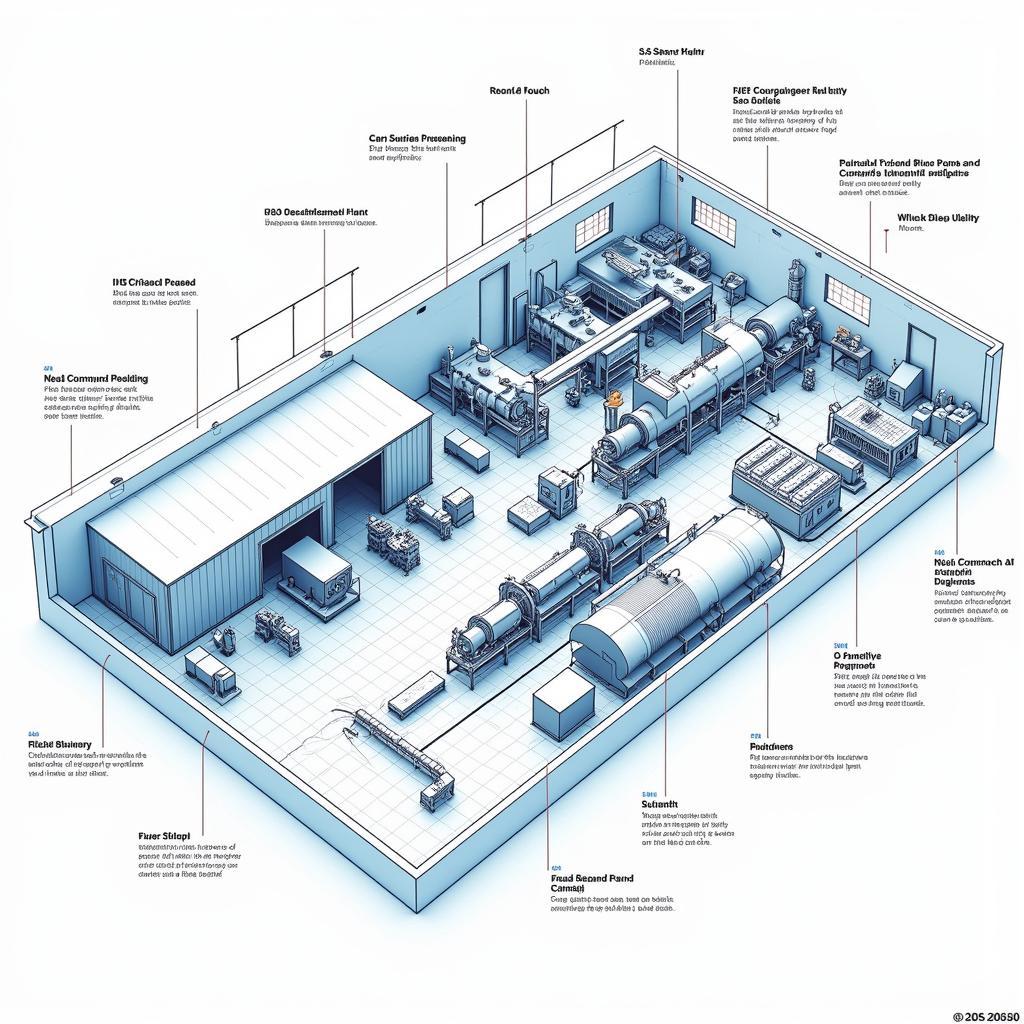

The design phase is the foundation upon which your entire food processing plant construction project rests. A well-thought-out design considers not only the specific food products being processed but also factors like workflow, hygiene regulations, future expansion, and sustainability. This stage involves close collaboration between architects, engineers, food technologists, and equipment suppliers to create a comprehensive plan that addresses all aspects of the facility. Key considerations include the layout of processing areas, efficient use of space, integration of utilities, and selection of appropriate materials that meet food safety standards. A robust design ensures a smooth construction process and a facility that operates efficiently and effectively for years to come.

Remember to factor in the specific requirements of your food processing operation. For example, a plant processing dairy products will have different needs compared to one handling fruits and vegetables. This includes considering the type of equipment, temperature control systems, and sanitation procedures necessary for each specific product.

Food Processing Plant Design and Layout

Food Processing Plant Design and Layout

Construction Phase: Bringing Your Food Processing Plant to Life

Once the design is finalized, the construction phase begins. This is where the blueprint translates into a tangible facility. This phase involves site preparation, foundation laying, erection of the building structure, installation of equipment, and connection of utilities. Effective project management is crucial during this stage to ensure that the construction stays on schedule and within budget. Regular communication and coordination between the construction team, equipment suppliers, and the client are essential to address any unforeseen challenges and ensure a seamless process.

Choosing the right construction materials is paramount. Materials used in food processing environments must be durable, resistant to corrosion, and easy to clean. They should also comply with all relevant food safety regulations. This is especially true for areas that come into direct contact with food.

Food Processing Plant Construction Site

Food Processing Plant Construction Site

Ensuring Long-Term Efficiency: Equipment Selection and Maintenance

Selecting the right equipment plays a vital role in the overall efficiency and productivity of your food processing plant. The equipment should be chosen based on the specific processing needs, capacity requirements, and technological advancements. Investing in high-quality, energy-efficient equipment can significantly reduce operating costs in the long run. Regular maintenance is essential to keep the equipment in optimal condition, minimizing downtime and ensuring the consistent quality of your food products. This involves routine inspections, cleaning, lubrication, and timely repairs.

A well-maintained plant is also essential for meeting food safety standards. Regular cleaning and sanitation prevent the growth of harmful bacteria and ensure the production of safe and wholesome food products. You can explore more about maintaining equipment components, like food grade bearings, on our website to learn about specialized solutions for the food industry.

Meeting Regulatory Requirements: Food Safety and Hygiene Standards

Food safety and hygiene are paramount in food processing plant construction. The facility must be designed and built to comply with all relevant regulations and standards. This includes implementing strict sanitation procedures, installing appropriate hygiene equipment, and training personnel on food safety practices. Regular inspections and audits are essential to ensure ongoing compliance and maintain the highest standards of food safety.

Consider consulting with food safety experts to ensure your plant meets all necessary regulations. They can provide valuable guidance on best practices and help you develop a comprehensive food safety plan.

Food Processing Plant Hygiene Standards

Food Processing Plant Hygiene Standards

Conclusion: Building a Sustainable and Profitable Food Processing Plant

Food processing plant construction is a significant investment, requiring careful planning and execution. By focusing on a robust design, selecting appropriate equipment, adhering to strict hygiene standards, and implementing effective maintenance procedures, you can build a sustainable and profitable food processing plant that delivers high-quality food products for years to come. Investing in a well-designed and constructed facility not only ensures the production of safe and wholesome food but also contributes to the long-term success of your business. Food processing plant construction is a journey, not a destination, and continuous improvement is key to staying ahead in the dynamic food industry.

FAQ

- What are the key factors to consider when choosing a location for a food processing plant?

- How can I ensure my food processing plant meets all regulatory requirements?

- What are the latest technological advancements in food processing equipment?

- How can I optimize energy efficiency in my food processing plant?

- What are the best practices for maintaining hygiene in a food processing environment?

- What are the different types of food processing plant layouts?

- How can I minimize downtime and maximize productivity in my food processing plant?

For further assistance, please contact us at Phone Number: 02437655121, Email: [email protected] Or visit us at: 3PGH+8R9, ĐT70A, thôn Trung, Bắc Từ Liêm, Hà Nội, Việt Nam. We have a 24/7 customer service team.