A well-designed Food Processing Floor Plan is the cornerstone of a successful food business. It dictates workflow efficiency, ensures food safety, and ultimately impacts your bottom line. This comprehensive guide will delve into the crucial aspects of creating a food processing floor plan that meets industry standards and optimizes your operations.

A food processing floor plan is much more than just arranging equipment. It’s a blueprint for success, incorporating elements of food safety, workflow optimization, and future scalability. Designing an effective layout requires careful consideration of various factors, from raw material receiving to finished product shipping. A poorly planned layout can lead to cross-contamination, inefficiencies, and even regulatory violations.

Key Considerations for Your Food Processing Floor Plan

Developing a robust food processing floor plan involves understanding and addressing several critical aspects. Let’s explore these elements in detail:

Workflow Optimization

An efficient workflow minimizes movement and maximizes productivity. Consider the logical flow of materials from receiving to processing, packaging, and shipping. A streamlined process reduces handling time, minimizes the risk of errors, and improves overall efficiency. Think of your floor plan as a well-choreographed dance, where each step contributes to the final performance.

- Raw Material Receiving: Designate a specific area for receiving raw materials. This area should be easily accessible for deliveries and equipped for proper storage and inspection.

- Pre-processing: Create a dedicated space for tasks such as washing, sorting, and preparing raw materials before processing.

- Processing Area: This is the heart of your operation. Arrange equipment to facilitate a smooth flow of materials through the various processing stages.

- Packaging and Labeling: Plan a designated area for packaging and labeling finished products, close to the processing area for easy access.

- Finished Goods Storage: Allocate sufficient space for storing finished products before shipping, ensuring proper temperature and humidity control.

- Shipping and Distribution: Designate a separate area for shipping and distribution, allowing for efficient loading and dispatch.

After this introductory section, let’s delve into the importance of food-grade flooring. Check out more information on food grade flooring.

Food Safety and Hygiene

Food safety is paramount in any food processing facility. Your floor plan should reflect this priority. Implement measures to prevent cross-contamination and ensure hygienic practices throughout the facility. This not only protects consumers but also safeguards your brand reputation.

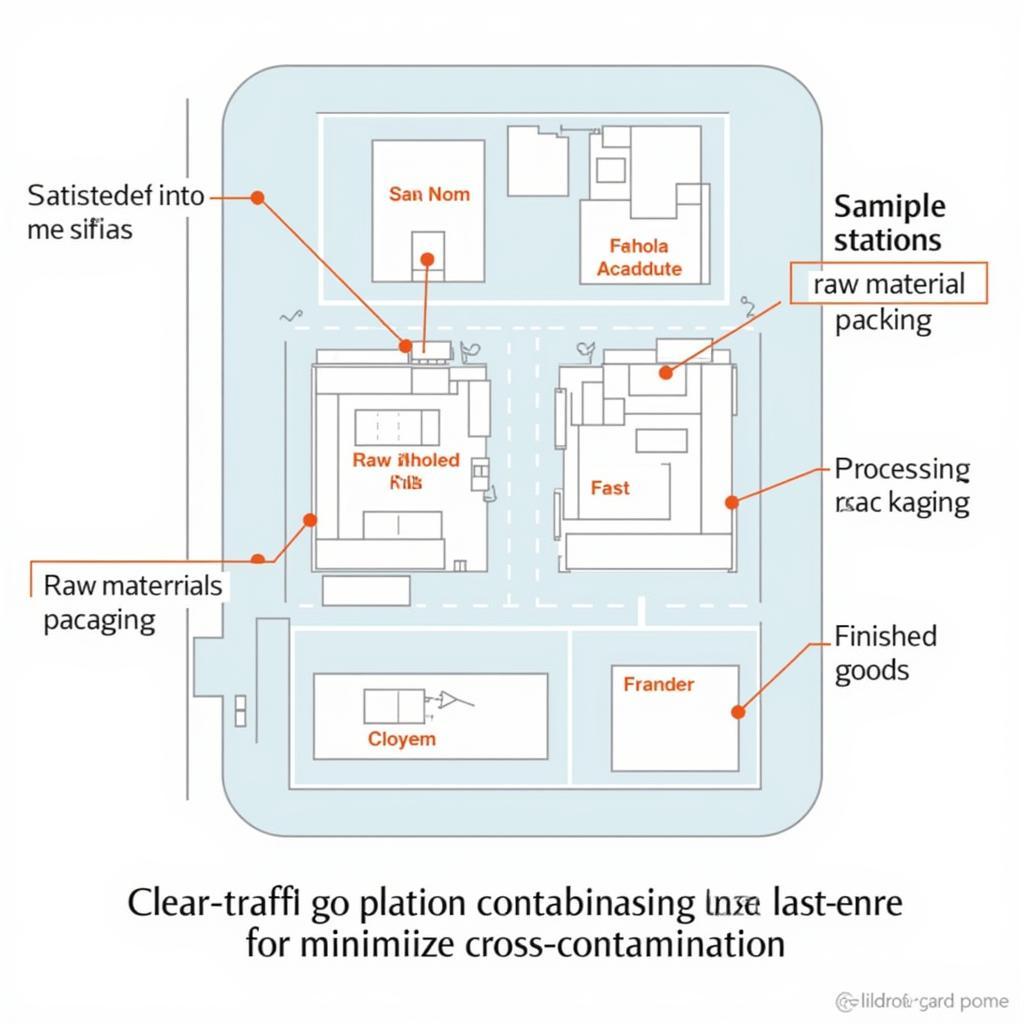

- Separate Zones: Designate separate zones for raw materials, processing, and finished products to minimize the risk of cross-contamination.

- Traffic Flow: Plan traffic flow to prevent crossovers between raw and cooked products. This can be achieved through designated walkways and separate entrances for raw materials and finished goods.

- Sanitation Stations: Strategically place handwashing sinks and sanitizing stations throughout the facility to encourage frequent hand hygiene among employees.

- Easy-to-Clean Surfaces: Choose materials and finishes that are easy to clean and sanitize, including floors, walls, and equipment surfaces.

Optimal Food Processing Facility Layout: Key Zones and Traffic Flow

Optimal Food Processing Facility Layout: Key Zones and Traffic Flow

Equipment Selection and Placement

Choosing the right equipment and placing it strategically is essential for optimal workflow and efficiency. Consider the size, capacity, and power requirements of each piece of equipment, ensuring sufficient space for operation and maintenance.

- Equipment Layout: Arrange equipment to minimize movement and maximize efficiency. Consider factors such as accessibility for maintenance and cleaning.

- Utility Connections: Ensure adequate utility connections (water, electricity, gas) are available for each piece of equipment.

- Space Optimization: Maximize space utilization by choosing the right size and type of equipment for your specific needs.

Remember, maintaining your equipment is crucial. A quality food equipment sanitizer can greatly enhance your hygiene protocols. Learn more about food equipment sanitizer.

Designing for the Future

A well-designed food processing floor plan should be adaptable to future growth and changes in demand. Consider scalability when designing your layout, allowing for expansion or modification without significant disruption to operations.

Scalability

- Future Expansion: Allocate space for potential future expansion of production lines or the addition of new equipment.

- Flexibility: Design the layout to accommodate changes in product lines or processing methods.

- Modular Design: Consider a modular design that allows for easy reconfiguration of the facility as needed.

Food Processing Floor Plan with Future Expansion in Mind

Food Processing Floor Plan with Future Expansion in Mind

Compliance and Regulations

Adhering to regulatory requirements is crucial for any food processing facility. Your floor plan must comply with local and national food safety regulations. Consult with relevant authorities to ensure your design meets all necessary standards.

- Food Safety Regulations: Ensure your floor plan complies with all applicable food safety regulations, including HACCP (Hazard Analysis and Critical Control Points).

- Building Codes: Adhere to local building codes and fire safety regulations.

- Accessibility: Ensure the facility is accessible for individuals with disabilities.

For certain specialized applications, a robust coating like the Rust-Oleum Food & Beverage Alkyd Enamel and Primer might be beneficial. You can find more details on rust-oleum food & beverage alkyd enamel and primer.

A Compliant Food Processing Floor Plan, Adhering to Safety and Hygiene Regulations

A Compliant Food Processing Floor Plan, Adhering to Safety and Hygiene Regulations

Conclusion

A well-designed food processing floor plan is the foundation of a successful and safe food business. By considering workflow optimization, food safety, equipment placement, scalability, and regulatory compliance, you can create a facility that maximizes efficiency, minimizes risks, and sets the stage for future growth. A carefully crafted food processing floor plan is an investment in the future of your business.

FAQ

- What is the importance of a food processing floor plan? A well-designed floor plan ensures efficiency, safety, and compliance.

- How do I optimize workflow in my food processing facility? Consider the logical flow of materials and minimize movement.

- What are the key food safety considerations for a floor plan? Separate zones, traffic flow control, and sanitation stations are crucial.

- How can I design for future scalability? Allocate space for expansion and consider a modular design.

- What regulations should I consider when designing a food processing floor plan? Comply with local and national food safety regulations and building codes.

- Where can I find more information on food truck concession windows? Check out this resource on food truck concession window.

- What about acquiring the necessary licenses for my food business? You can learn more about food license iowa.

Need help with food business licensing? Or perhaps advice on concession window designs for your food truck? We offer a wealth of information on these topics and more.

For further assistance, contact us at Phone Number: 02437655121, Email: minacones@gmail.com or visit our office at 3PGH+8R9, ĐT70A, thôn Trung, Bắc Từ Liêm, Hà Nội, Việt Nam. Our customer support team is available 24/7.