An Industrial Food Blender is more than just a kitchen appliance; it’s a game-changer for food businesses of all sizes. Whether you’re a bustling restaurant, a growing catering service, or a passionate food entrepreneur, these heavy-duty machines empower you to create large batches of perfectly blended ingredients with unmatched speed and consistency. But with so many options on the market, how do you choose the right industrial food blender for your specific needs? Let’s dive into the world of industrial food blenders and explore everything you need to know to make an informed decision.

Why Invest in an Industrial Food Blender?

For food businesses serious about efficiency, quality, and scalability, an industrial food blender is a non-negotiable asset. Here’s why:

-

Increased Productivity: Industrial food blenders can handle significantly larger volumes than standard blenders, allowing you to produce more in less time. This is especially crucial for businesses with high-volume demands, such as restaurants, cafes, and food manufacturers.

-

Superior Consistency: These powerful machines are designed to deliver consistently smooth and even results, batch after batch. This level of precision is essential for maintaining product quality and customer satisfaction.

-

Versatility at its Finest: From smoothies and soups to sauces and dips, industrial food blenders can handle a wide range of ingredients and recipes. Many models come equipped with various speed settings and pre-programmed cycles, allowing you to achieve the perfect texture for any culinary creation.

-

Built to Last: Constructed with durability in mind, industrial food blenders are built to withstand the rigors of daily commercial use. Investing in a high-quality machine ensures longevity and a high return on investment.

Choosing the Right Industrial Food Blender: Key Factors to Consider

Navigating the world of industrial food blenders can feel overwhelming, but understanding your specific requirements and the key features that matter most can simplify the selection process.

1. Capacity and Power: How Much Can It Handle?

The first step is determining the volume of ingredients you typically process. Industrial food blenders come in a range of capacities, from compact countertop models to large-capacity floor-standing units. Consider your average batch sizes and choose a blender that can comfortably accommodate your needs. Additionally, assess the power of the motor, measured in horsepower (HP). A higher HP generally translates to faster blending and smoother results, especially for tougher ingredients.

2. Functionality and Settings: What Can It Do?

Beyond basic blending, many industrial food blenders offer a variety of functions to enhance your culinary capabilities. Some common features include:

-

Variable Speed Control: Allows for precise adjustments to achieve the desired texture, from coarse chopping to silky smooth purees.

-

Pre-Programmed Cycles: Simplify the blending process with pre-set cycles optimized for specific tasks, such as smoothies, soups, or frozen drinks.

-

Pulse Function: Provides short bursts of power for greater control and precision, ideal for chopping delicate ingredients or achieving a chunky texture.

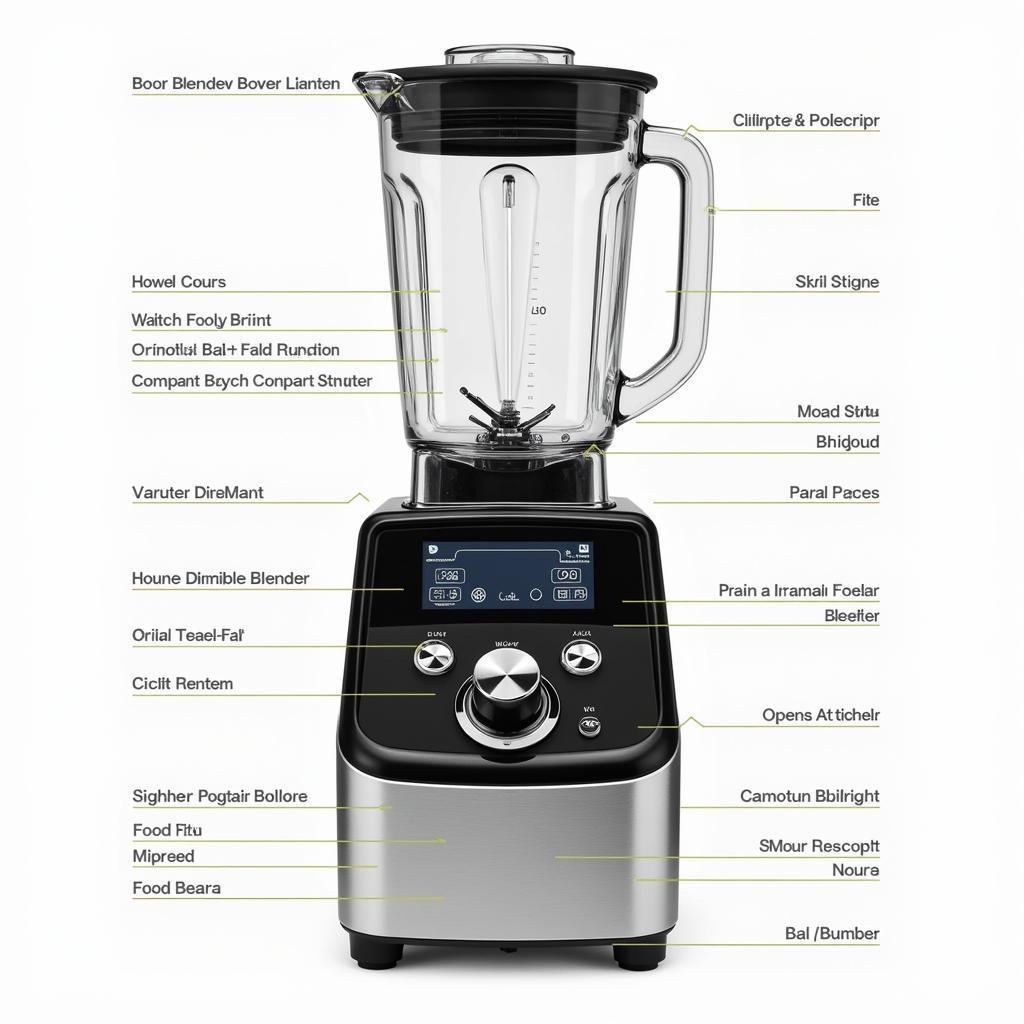

Industrial Food Blender Control Panel Close-Up

Industrial Food Blender Control Panel Close-Up

3. Durability and Construction: Is It Built to Last?

Investing in a robust and reliable industrial food blender is crucial for long-term performance and minimal downtime. Look for machines constructed with high-quality materials, such as stainless steel, which offers excellent durability, corrosion resistance, and ease of cleaning.

“When choosing an industrial food blender, durability is non-negotiable,” says Chef Daniel Miller, a veteran chef with over 20 years of experience in commercial kitchens. “A well-built machine can withstand daily wear and tear, ensuring consistent performance for years to come.”

4. Ease of Cleaning and Maintenance: Can You Keep It Hygienic?

Maintaining a clean and sanitary food preparation environment is paramount. Look for industrial food blenders with features that simplify cleaning, such as:

-

Removable Parts: Dishwasher-safe components, like the blender jar and lid, make cleaning quick and easy.

-

Smooth Surfaces: Blenders with minimal crevices and grooves prevent food particles from getting trapped, reducing the risk of bacterial growth.

Exploring Applications: What Can You Create?

The culinary possibilities with an industrial food blender are virtually limitless. From creamy bisques and velvety smooth sauces to refreshing smoothies and vibrant salsas, these versatile machines can elevate your menu and streamline your food preparation process. Here are just a few examples of how different businesses utilize industrial food blenders:

-

Restaurants: Prepare large batches of signature soups, sauces, dressings, and dips with ease, ensuring consistent flavor and texture for every dish.

-

Cafes and Coffee Shops: Craft perfect smoothies, frozen coffee drinks, and other blended beverages in seconds, keeping up with high customer demand during peak hours.

-

Bakeries: Create smooth batters for cakes, cookies, and other baked goods, ensuring even mixing and consistent results.

-

Catering Services: Prepare large quantities of soups, sauces, dips, and spreads for catered events, maintaining quality and efficiency for high-volume orders.

Conclusion: Elevate Your Culinary Game

Investing in an industrial food blender is a strategic decision that can significantly enhance your food business’s efficiency, consistency, and overall success. By carefully considering your specific needs and the key features discussed in this guide, you can choose the perfect machine to elevate your culinary creations and streamline your operations.

Remember, an industrial food blender is an investment in your business’s future, empowering you to meet growing demands, maintain impeccable quality standards, and unlock your culinary creativity.

Frequently Asked Questions About Industrial Food Blenders

1. How often should I clean my industrial food blender?

It’s crucial to clean your industrial food blender after each use to prevent cross-contamination and ensure food safety.

2. Can I blend hot liquids in an industrial food blender?

While some models are designed to handle hot liquids, it’s essential to check the manufacturer’s instructions as extreme temperatures can damage certain components.

3. What is the average lifespan of an industrial food blender?

With proper care and maintenance, a high-quality industrial food blender can last for several years, even with daily use.

4. What are some common signs that my industrial food blender needs repair?

Unusual noises, leaking seals, or a burning smell are all indicators that your blender requires professional attention.

5. Where can I find reliable repair services for my industrial food blender?

For all your food processing equipment needs, including repairs and maintenance, visit food processing equipment repair. Our expert technicians can diagnose and resolve any issues, ensuring your equipment runs smoothly.

Need Help Choosing the Right Equipment?

Selecting the right equipment for your food business can be a significant decision. If you have any questions or need guidance choosing the best industrial food blender or other food processing supplies, don’t hesitate to contact us. Our team of experts is here to assist you.

At Mina Cones Food, we offer a comprehensive range of food and beverage processing equipment and top-quality food grade lube to keep your operations running smoothly.

Contact us today:

Phone: 02437655121

Email: [email protected]

Address: 3PGH+8R9, ĐT70A, thôn Trung, Bắc Từ Liêm, Hà Nội, Việt Nam

Our customer support team is available 24/7 to answer your questions and provide expert advice.